Andrew Mafu Machinery (ADMF) recently showcased its Napoleon Cake Pastry Forming Production Line through a live production demonstration, highlighting the capabilities of automated pastry forming technology for layered cake and puff pastry products. The demonstration focused on the forming and handling process of Napoleon cake (also known as mille-feuille), a product known for its delicate layers, precise dough handling requirements, and high demands on consistency.

The video presentation reflects ADMF’s continuous focus on providing industrial bakeries and pastry manufacturers with stable, efficient, and scalable automation solutions for complex pastry products.

Automated Forming Technology for Layered Pastry Products

Napoleon cake production presents unique challenges in industrial environments. Unlike standard bread products, layered pastries require precise control of dough thickness, cutting accuracy, alignment, and gentle handling to preserve the structure of the layers.

The ADMF Napoleon Cake Pastry Forming Production Line is designed specifically to address these challenges by integrating controlled forming, synchronized conveying, and automated positioning into a continuous workflow.

During the demonstration, the forming line showed smooth dough transfer, accurate shaping, and stable rhythm, ensuring that each pastry piece maintained uniform dimensions and layer integrity throughout the process.

Click the YouTube link to watch the Napoleon puff pastry dough forming line:

https://youtube.com/shorts/j7e05SLkziU

How the Napoleon Cake Pastry Forming Production Line Works

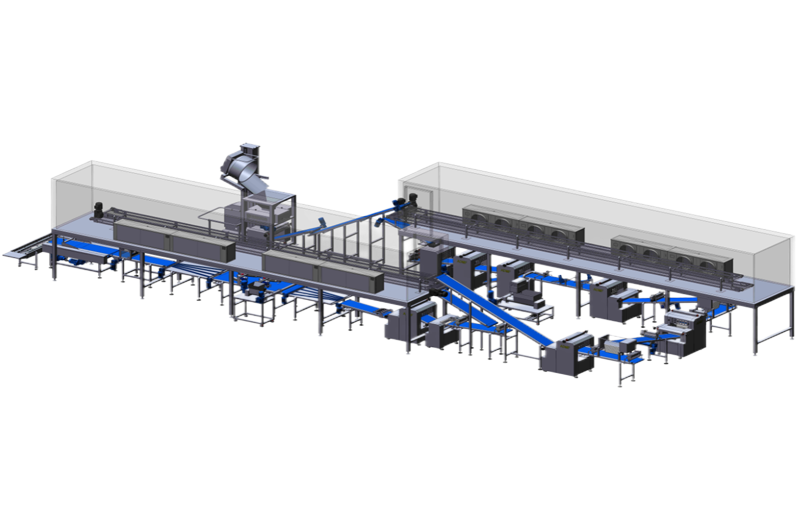

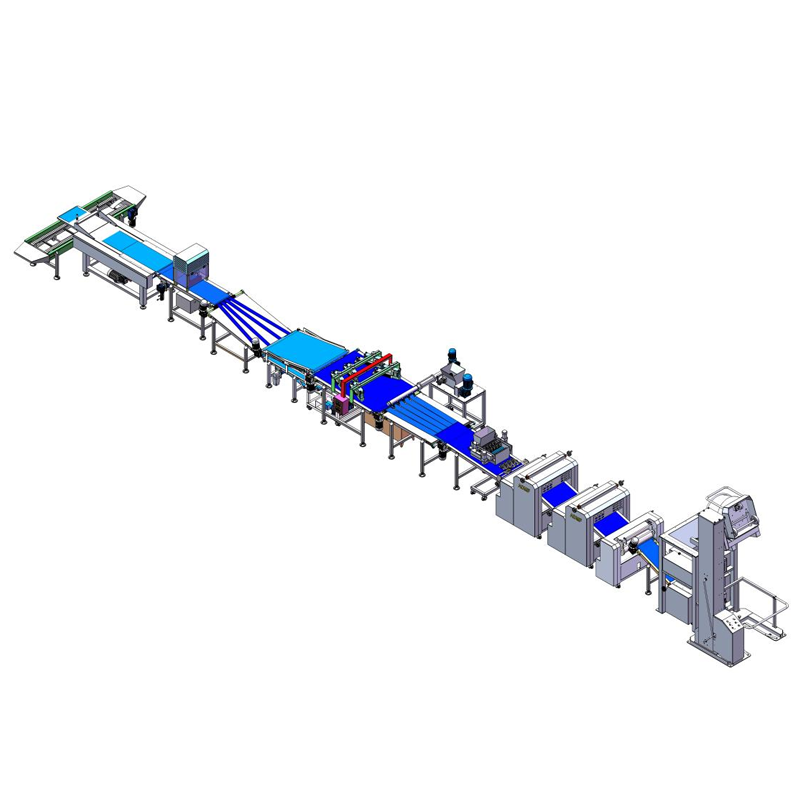

The ADMF production line adopts a modular design that allows different forming and handling units to work in coordination. The typical forming process includes:

-

Dough Feeding and Alignment

Prepared laminated dough sheets are fed into the system with precise positioning to ensure consistent processing.

-

Pastry Forming and Shaping

The forming unit shapes the dough into standardized Napoleon cake portions, maintaining even thickness and clean edges.

-

Synchronized Conveying

Automated conveyors transfer formed pastry pieces smoothly, minimizing deformation and layer displacement.

-

Tray Arrangement and Transfer

Finished pieces are accurately positioned for downstream baking, freezing, or packaging operations.

The entire process is controlled through an industrial PLC system, allowing operators to monitor production parameters and maintain stable output.

Key Technical Advantages of the ADMF Napoleon Cake Forming Line

The production line demonstrated several technical advantages that are particularly important for layered pastry manufacturing:

Precision and Consistency

The forming system ensures uniform size and shape across batches, which is essential for both baking performance and final product presentation.

Gentle Dough Handling

Mechanical design focuses on minimizing stress on laminated dough, preserving layer separation and structure.

Automation and Labor Efficiency

By replacing manual forming and handling, the line significantly reduces labor dependency while improving production consistency.

Stable Industrial Operation

Built with industrial-grade components, the system supports continuous operation in high-demand production environments.

Flexible Integration

The forming line can be integrated into existing pastry production workflows or combined with upstream lamination and downstream baking systems.

Production Line Technical Parameters:

| Item | Specification |

| Equipment Model | ADMF-400 / ADMF-600 |

| Produkzio gaitasuna | 1.0 – 1.45 tons per hour |

| Machine Dimensions (L × W × H) | 22.9 m × 7.44 m × 3.37 m |

| Total Installed Power | 90.5 kW |

Application Scenarios for Industrial Pastry Manufacturers

The ADMF Napoleon Cake Pastry Forming Production Line is suitable for a wide range of applications, including:

-

Industrial bakeries producing Napoleon cake or mille-feuille

-

Pastry factories supplying retail chains and food service customers

-

Frozen pastry manufacturers requiring consistent forming before freezing

-

Central kitchens focusing on standardized layered pastry products

By adopting automated forming solutions, manufacturers can better control product quality while increasing output capacity.

Engineering Perspective: Automation for Layered Pastry Products

From an engineering standpoint, layered pastry automation requires a balance between precision and flexibility. During the demonstration, the ADMF forming line illustrated how mechanical synchronization and controlled motion can replace manual operations without compromising product quality.

Key engineering considerations include:

-

Accurate positioning of laminated dough

-

Controlled forming pressure to avoid layer damage

-

Stable conveying speed to maintain production rhythm

-

Hygienic design for easy cleaning and maintenance

These principles are reflected in the design of the ADMF Napoleon Cake Pastry Forming Production Line.

Industry Trend: Growing Demand for Automated Pastry Forming

As market demand for premium pastry products continues to grow, manufacturers are increasingly looking for automation solutions that can handle complex products like Napoleon cake.

Automation not only improves consistency but also supports scalability, allowing producers to meet increasing order volumes while maintaining quality standards. The demonstration of the ADMF forming line highlights how modern pastry production is shifting toward intelligent, automated systems.

Andrew Mafu Machinery has extensive experience in automated bakery and pastry production lines. Rather than focusing solely on individual machines, ADMF emphasizes system-level solutions that integrate forming, conveying, and handling into cohesive production lines.

This approach allows customers to move toward full automation step by step, based on their production scale and product requirements.

1. What types of pastries can this forming line handle?

The line is suitable for Napoleon cake, mille-feuille, and other layered or laminated pastry products with similar forming requirements.

2. Can the forming line be customized for different product sizes?

Yes. Forming dimensions and layout can be adjusted based on product specifications.

3. Is the system suitable for frozen pastry production?

Yes. The line can be integrated with freezing and downstream handling systems.

4. How does the line protect laminated dough layers?

Through controlled forming pressure, smooth conveying, and precise mechanical synchronization.

5. Can this line be integrated into an existing production line?

Yes. The modular design allows flexible integration with upstream and downstream equipment.

References & Sources

- Automation Solutions for Layered Pastry Production,Bake Magazine

- Industrial Pastry Manufacturing and Forming Technology,Food Processing

- Design Principles for Automated Bakery Production Lines,Andrew Mafu Makineria