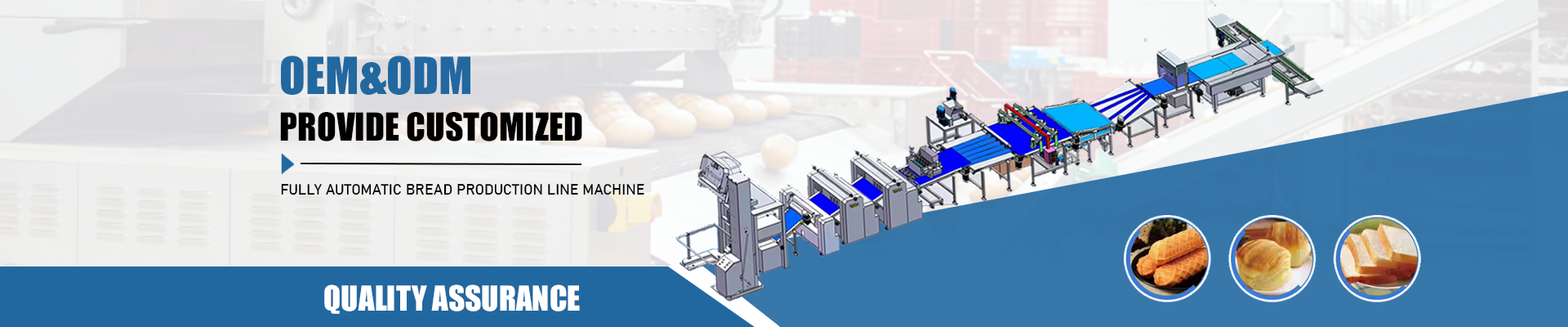

Andrew Mafu Machinery Unveils Adventing Automated Sandwich Ntau Lawm, Tararing Ntiaj Teb Cov Khoom Noj Khoom Noj

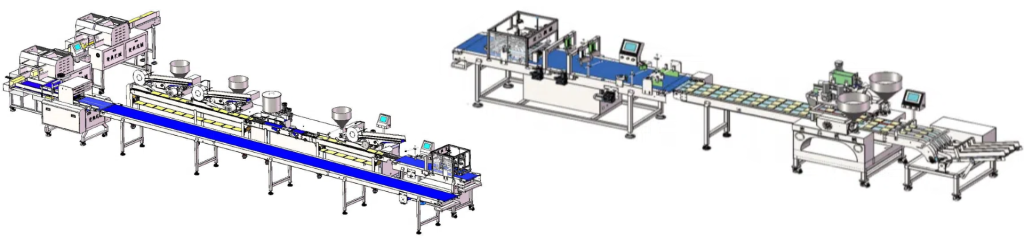

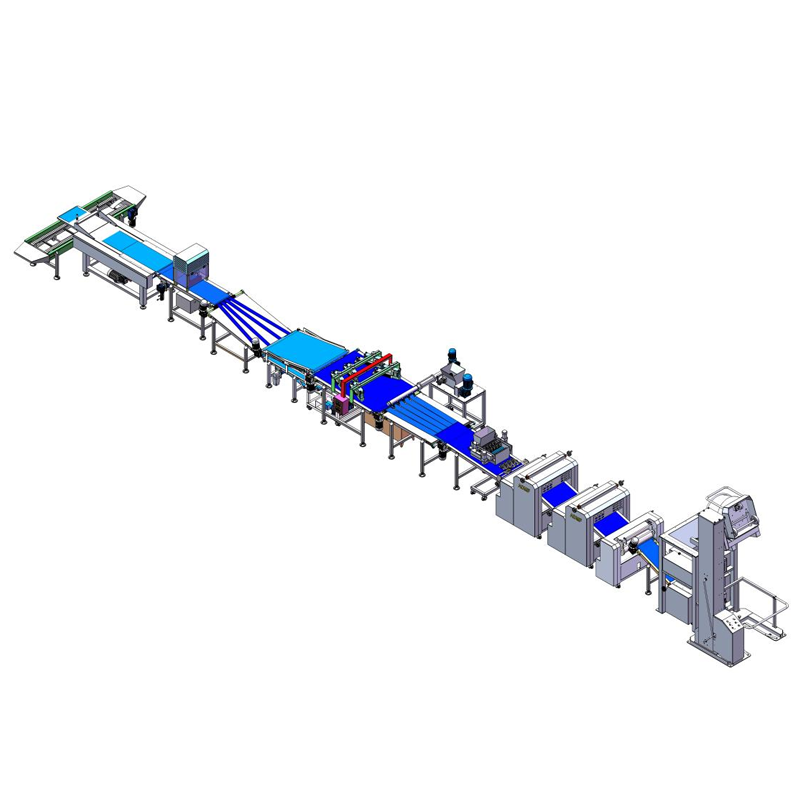

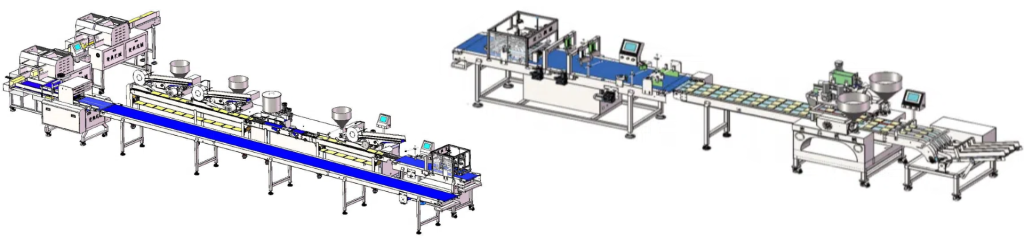

Nyob rau hauv ib qho tseem ceeb txav mus rau reschape ua haujlwm thiab cov qauv kev sib xws hauv cov khoom noj khoom haus ua khoom noj hauv cov khoom noj khoom haus, tag nrho cov kab ntau lawm. Siv Lub Tshuab Tshwj Xeeb Cov Kev Sib Koom Tes Loj ntawm cov tshuab tshwj xeeb, cov qhob txuas ntxiv ua ke, ci tshuab sau tshuab, thiab tshuab ultrasonic txiav. Cov kab cog lus ntau ntxiv hauv kev tawm, kev tu cev, kev nyiam huv, thiab cov hauj lwm raug nqi rau cov neeg tsim khoom thoob ntiaj teb.

Ntiaj teb kev ua lag luam nyuaj thoob ntiaj teb, encomppassing khw muag khoom, FoodService, thiab cov ntu kev sib koom ua ke, tseem muaj kev loj hlob trajectory. Txawm li cas los xij, cov chaw tsim khoom sib ntsib ntsej muag tsis tu ncua: nce kev tswj hwm khoom noj kev nyab xeeb, thov kom zoo ua kom zoo, thiab qhov xav tau sai dhau los ua kom tiav lub ntim. Andrew Mafu txoj kab tshiab yog engineered tshwj xeeb kom kov yeej cov hurdles, muab cov tshuaj turney rau kev tsim cov qhaub cij ntawm nplai.

"Cov neeg tsim khoom tshiab niaj hnub xav tau ntau dua li nrawm; lawv xav tau kev sib raug zoo, kev txiav kom huv, thiab cov neeg nyiam huv si, thiab kev sib xyaw ua kom huv si,"Tau hais Mr. Alex Chen, lub taub hau muag khoom & ua lag luam ntawm Andrew Mafu tshuab. "Peb cov kab ntau lawm tua pov tseg cov zaub bottling, minimizes kev txhais tes tuav, thiab muab rho tawm. Qhov no tsis yog cov qhaub cij engineering."

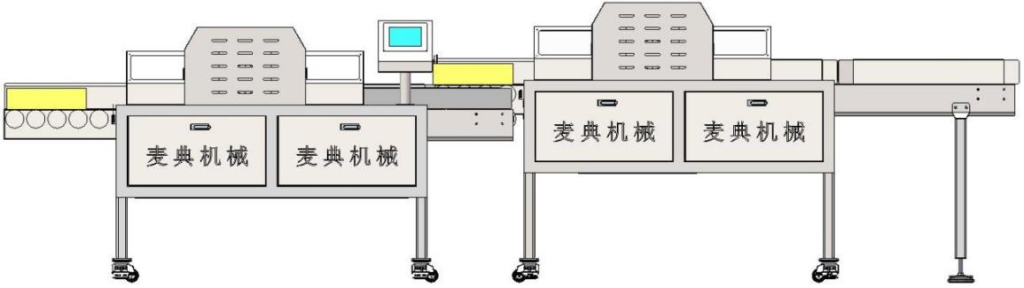

Deconstructing Kab: Cov Cheebtsam Tseem Ceeb & Cov Haujlwm

1. Toua zaub tshuab:

Ua Haujlwm: Qhov tseem ceeb thawj theem chaw nyob cov teeb meem uas muaj ib qho kev sib cais ua ke yooj yim toasted lossis cov ncuav cij ua ntej ci uas yuav lo ua ke tom qab ntim khoom lossis thaum tuav. Lub tshuab maj mam muab thiab ntseeg tau peed tus txiv hmab ib leeg slices los ntawm ib pawg, nthuav qhia lawv kom raug rau lwm theem tom ntej. Nws ua haujlwm tshwj xeeb tshuab (feem ntau yog siv cov ntiv nplhaib nqus, cov ntiv tes ua kom zoo lossis kho kom zoo nkauj tsis muaj kev ntuag lossis deformation.

Cuam tshuam: Ua kom muaj kev ywj siab, tsis muaj kev cuam tshuam rau hauv lub tshuab slicing, tiv thaiv jams thiab downtime tshwm sim los ntawm nyam cov nplais. Qhov tseem ceeb rau kev tswj hwm kab nrawm thiab tshem tawm qhov xav tau kev sib cais, ib kauj ruam tseem ceeb.

2. Nruam qhob cij slicing tshuab:

Ua Haujlwm:Puag tom qab teeting, lub tshuab ceev no siv cov ib tus zuj zus uas yuav tsum muaj rau cov tuab silwich (piv txwv li cov khoom siv tshuaj yej, tus qauv rau su qhaub cij). Nws ua haujlwm tsis tu ncua, synchronizing zoo kawg nkaus nrog cov tev ua kom pom tseeb thiab cov chaw nres tsheb tso tawm. Nta muaj xws li ultra-ntse, cov khoom noj-me me stainless hlau tuaj, kho tuab tuab sitse cov chaw, thiab feem ntau tsis siv neeg cov hniav hliav rau kev ua tau zoo ib yam.

Cuam tshuam: Xa cov khoom tsis zoo nkauj ncuav slices tseem ceeb rau kev ua haujlwm nyuaj, tsos, thiab siv hluav taws xob hauv tsev. Hloov qeeb qeeb, tsis muaj lus qhia tsawg dua los sis semi-automatic slicers, hloov zuj zus mus los ntawm kev sib tw thiab hlais.

3. Cij filling tshuab:

Ua Haujlwm: Lub plawv ntawm cov qhaub cij sib dhos. Lub tshuab txawj ntse no meej meej qhia txog cov tshuaj uas ntsuas (cov zaub noj, cov zaub nyoos, lossis sib txuas ua ke) mus rau qhov chaw nres tsheb. Nyob ntawm tus qauv thiab kev teeb tsa, nws tuaj yeem tswj tau ntau yam kev sib tw ua ke lossis ua ntu zus rau cov chunks, muaj teeb meem, ua kom zoo rau cov nplais). Cov qauv qhia tau muaj cov ntawv qhia muaj cov ntawv qhia kev tswj hwm rau ntau hom qhaandwich.

Cuam tshuam:Ua tiav qhov tseeb feem tswj feem, tseem ceeb rau kev tswj hwm tus nqi thiab kev sib tham cov khoom lag luam cov khoom lag luam. Ua kom tiav kev sib sau ua kom tiav thiab faib khoom, txhim kho cov khoom lag luam zoo thiab ntsej muag. Tseem ceeb txo cov nqi zog uas cuam tshuam nrog kev sib sau ua ke thiab txo qis khib nyiab pov tseg. Saib xyuas kev huv los ntawm cov txheej txheem ua tiav.

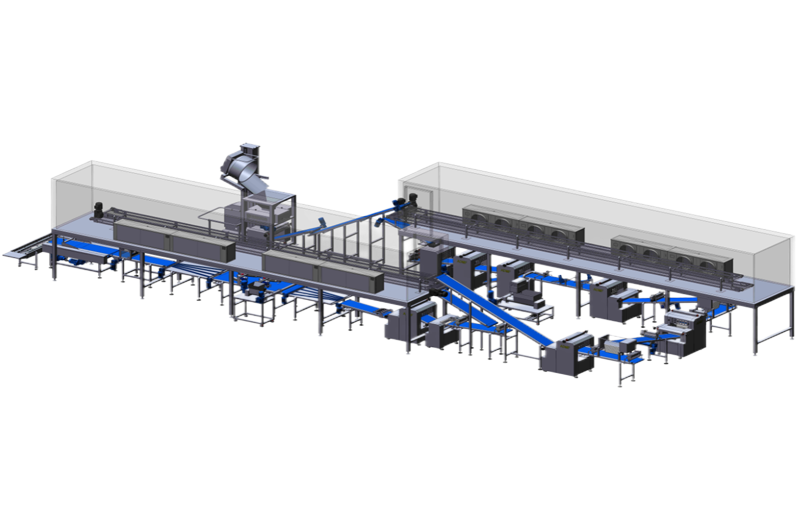

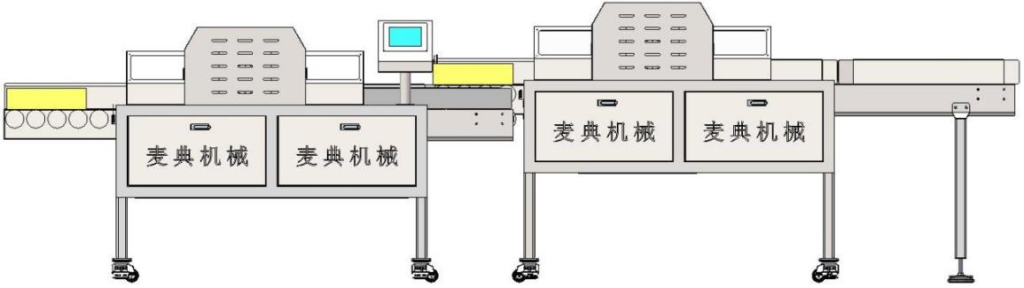

4. Ultrasonic tej tshuab:

Ua Haujlwm: Qhov no sawv cev txoj kev txiav-ntug (lus) ntawm kab. Hloov cov tshuaj ib txwm ua, cov tshuab no siv high-zaus ultrasonic deeg los tsim cov cua sov ntawm theem molecular raws txoj kev txiav. Nws kom huv si thiab kho kom zoo yog cov qhaub cij kom puv rau hauv halves, ib hlis, duab peb sab, lossis lwm yam duab raws li cov txheej txheem.

Cuam tshuam:

Huv huv txiav: Zoo nkaus li tshem tawm cov crumbbs, smearing, thiab sau tej chaw kaw ("nyem-tawm") ua rau muaj pristine, khoom lag luam.

Ntim Ntim:Cov txheej txheem kub hauv zos tsim los ntawm cov txheej txheem ultrasonic muaj peev xwm me ntsis los yog ntim cov npoo ntawm qee cov txheej txheem (zoo li cheese) thiab cov mov, muaj peev xwm txuas lub neej me ntsis.

Kev nyiam huv & txij nkawm: tsis muaj kev sib ze txiav (lub Horn tsis kov cov zaub mov ncaj qha) thiab tsis yooj yim txoj kev kho kom huv thiab yooj yim tu. Cov tshuab ultrasonic feem ntau yuav tsum tau muaj kev txij nkawm tsawg dua li cov kws cutters zoo siv.

Versatility: Excel ntawm kev txiav cov qhaub cij nrog cov nplaum, noo, lossis ntau-fawm txheej uas yuav ua rau cov hniav sib xyaw.

Cov txiaj ntsig kev sib xyaw:

Lub zog tseeb ntawm tus Andrew Mafu kab lus nyob hauv kev sib koom ua ke ntawm plaub lub tshuab tshwj xeeb. Conveyor tshuab synchronize lub zog ntawm cov khoom ntawm txhua theem, kom ua rau kev ua haujlwm du, ua haujlwm tas mus li. Cov tswj hwm logicmable (PLCS) tswj cov txheej txheem tag nrho, tso cai rau cov ntawv qhia yooj yim hloov, kev kho kom haum nrawm, thiab kev saib xyuas cov ntsiab lus tseem ceeb. Cov kab yog tsim nrog zaub mov-qib stainless hlau thoob plaws, thiab yooj yim ntawm kev ntxuav cov qauv hauv ntiaj teb (HACCP, ISO 22000).

Machineries tej tshuab ultrasonic txiav

Cov ntsiab lus tseem ceeb rau cov tuam txhab muaj:

Ua tsaug ntau ntxiv: Muaj peev xwm ua ntau pua, txawm tias ntau txhiab, ntawm cov qhaub cij ib teev twg, deb tshaj phau ntawv lossis ib nrab tshuab xwb.

Txhim kho ib txwm & Zoo: Cov khaub ncaws thooj tuab, ua kom haum siv cov tes taw hnyav li, thiab kev tso kawm thiab huv si tov cov xuab zeb ua tau raws li cov lus qhia tshwj xeeb.

Qhov tseem ceeb ua haujlwm txo:Automates feem ntau cov txheej txheem ua haujlwm tshaj plaws (teeling, slicing, txiav), txo cov haujlwm pub dawb rau cov neeg muaj nqis ntau dua rau cov neeg loj.

Txhim Kho Kev Lom Zem & Kev Nyab Xeeb Khoom Noj: Tus neeg tsis muaj neeg, nrog kev sau ua ke, tsim qauv yooj yim, thiab ultrasonic txiav tag nrho cov kev pab rau kev nyab xeeb ib puag ncig.

Txo cov khib nyiab:Precise seem tswj ntawm cov ntawv sau thiab ntxuav kom huv cov khoom giveaway thiab txeej.

Scalability:Cov qauv tsim qauv tso cai rau kev nthuav dav yav tom ntej lossis kev koom ua ke nrog cov txheej txheem ntws los / cov txheej txheem ci (ci, txias, ntim).

Kev ua lag luam txoj hauj lwm & muaj:

Tus Andrew Mafwich Ntau Lawm Kab yog lub hom phiaj rau cov chaw ua zaub mov loj Lub tuam txhab hais txog cov peev xwm rau kev hloov kho kom coj ntau hom ncuav (dawb, tag nrho cov zaub mov noj, thiab cov khoom lag luam muag khoom thiab qhov ntau thiab tsawg.

Qhov kev tso tawm no Andrew Mafu mafu mafu mafu mafue khov kho nyob rau hauv kev cog qoob loo ntawm kev daws teeb meem automation rau kev npaj cov zaubmov. Raws li kev ua haujlwm luv luv tsis tu ncua thiab kev xav tau zoo nce, cov kab kev sib xyaw ua ke ntawm kev nqis peev los ntawm kev nqis peev los ntawm kev ua tau zoo thiab txhim kho khoom ncaj ncees.

Kev muag khoom rau kev muag khoom nug & cov ncauj lus qhia ntxaws ntxaws:

Cov tuam txhab txaus siab kawm ntxiv txog tus Andrew mafu sandwich ntau lawm kab, thov kom muaj cov ntawv sau cia, lossis txhawb pab Andrew Mafu muag pab pawg:

Xov tooj / WeChat / WhatsApp: +86 184 0598 6446

Email: [email protected]

Lub Vev Xaib:https://www.andrewmofUGroup.com/

Hais txog Andrew Mafu Machinery:

Andrew mafu Machinery yog cov chaw tsim khoom muaj npe thiab cov khoom siv ntawm cov zaub mov zoo ua tshuab ua tshuab ua ke hauv Suav teb. Nrog rau xyoo ntawm kev ua lag luam kev lag luam, tuam txhab tshwj xeeb hauv kev tsim qauv thiab cov khoom lag luam tshiab, thiab khoom noj khoom haus, khoom noj txom ncauj, thiab npaj-noj mov. Lawv txoj kev mob siab rau qhov zoo, kev pabcuam cov neeg siv khoom, thiab kev txhim kho thev naus laus zis tau tsim lawv ua tus neeg koom nrog cov chaw tsim khoom noj hauv ntiaj teb.

Los ntawm admf