Kuwongolera kwa PLC mu Mizere Yamakono Yopangira Mkate

M'dziko lamakampani ophika buledi, Programmable Logic Controllers (PLC) ndi mphamvu yosaoneka yowonetsetsa kuti mkate uliwonse waphikidwa bwino.

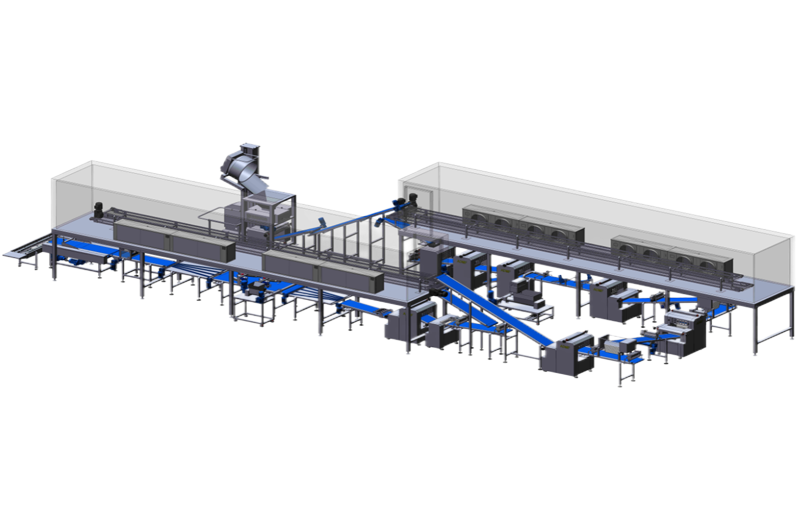

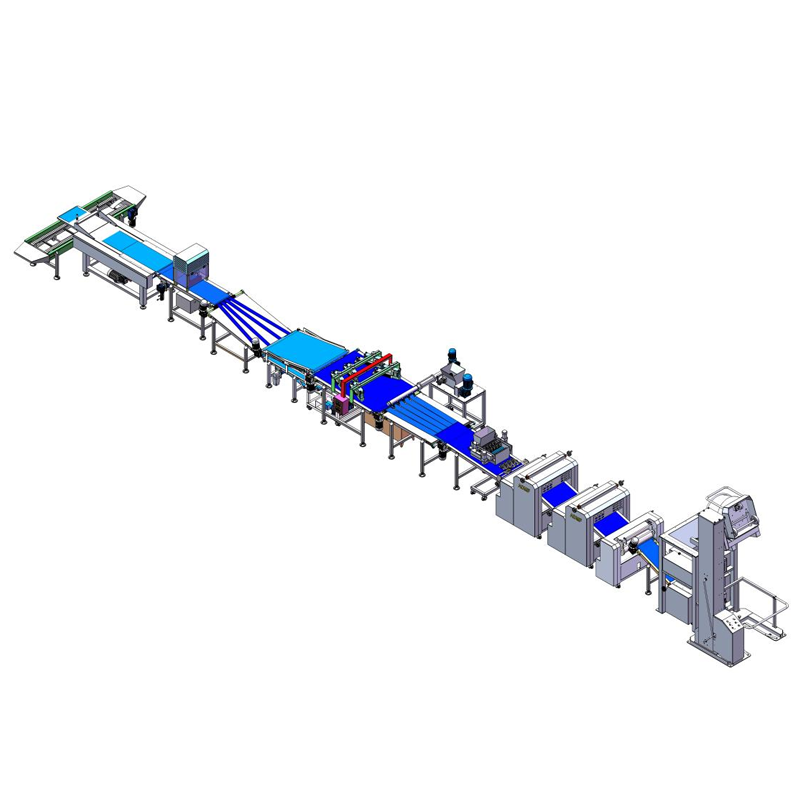

Amakhala ngati "ubongo" wa mizere yopangira mkate yokha, zolumikizira zosanganikirana, zotsimikizira, mauvuni, ndi zotengera zinthu kukhala dongosolo logwirizana komanso lanzeru.

Pamene malo ophika buledi padziko lonse lapansi akukumana ndi kukwera mtengo kwa ogwira ntchito komanso miyezo yolimba yachitetezo cha chakudya, PLC yoyendetsedwa ndi makina opangira zakhala zofunikira.

Kuphatikiza kulondola, kuchita bwino, komanso kuwonekera kwa data, makina a PLC amasintha njira zophika buledi kukhala njira zopangira zanzeru, zodziwikiratu, komanso zotsatirika.

Kodi PLC System mu Bakery Production ndi chiyani?

A PLC (Programmable Logic Controller) ndi kompyuta yolimba yamakampani yopangidwa kuti iziwongolera makina munthawi yeniyeni.

Imalandira zidziwitso kuchokera ku masensa, imapanga malingaliro okonzedwa, ndikusintha makina ogwiritsira ntchito nthawi yomweyo.

Popanga buledi, ma PLC amawunika zosintha zazikulu monga:

-

Mtanda kusakaniza torque ndi kutentha

-

Kutsimikizira chinyezi ndi kufalikira kwa mpweya

-

Kugawa kutentha kwa uvuni ndi nthawi yake

-

Kulumikizana kwa conveyor

-

Kuziziritsa ndi slicing kugwirizana

Owongolera awa amapangidwa kuti azigwira ntchito mosalekeza m'malo otentha kwambiri, okhala ndi chinyezi chambiri, kuonetsetsa 24/7 kudalirika ndi kulowererapo kochepa kwa anthu.

Chifukwa Chake PLC Systems Ndi Yofunikira mu Bakery Automation

Popanda ma PLC, njira zophika buledi zimatengera kuweruza kwa wogwiritsa ntchito - nthawi zambiri zomwe zimapangitsa kuti mtanda ukhale wosagwirizana kapena kuphika kosafanana.

Dongosolo la PLC likayambitsidwa, gawo lililonse limakhala loyezeka komanso lowongolera, kutsimikizira zotsatira zokhazikika.

| Mbali | Manual System | Ndi PLC Integration |

| Kuwongolera Kutentha | Kutengera zomwe zidachitika | ± 1°C kulondola kodziwikiratu |

| Kusakaniza & Kutsimikizira | Zotengera nthawi | Kuwongolera mayankho oyendetsedwa ndi sensa |

| Magwiridwe Ovuni | Oyendetsa asinthidwa | Programmable zone Kutentha |

| Kugwiritsa Ntchito Mphamvu | Zosakwanira | 15-25% yopulumutsa ndi kukhathamiritsa |

| Product Uniformity | Zosintha | Zogwirizana pamagulu onse |

Malinga ndi kafukufuku wamakampani, ophika buledi omwe amagwiritsa ntchito PLC automation experience mpaka 30% kuchita bwino kwambiri ndi kwambiri kuchepetsa zinyalala .

Momwe PLC Imathandizira Gawo Lililonse Lopanga Mkate

1. Kuwongolera Kusakaniza kwa Mtanda

Ma PLC amayezera kukana kwa mtanda ndi kutentha kuti musinthe liwiro losakanikirana.

Izi zimatsimikizira kukhazikika kwa gilateni ndi hydration, kuthetsa kusiyana kwa batch-to-batch.

2. Kutsimikizira ndi nayonso mphamvu

Sensa ya chinyezi ndi kutentha imapereka mayankho a nthawi yeniyeni ku PLC, kusunga kuwira kosasinthasintha pagulu lililonse.

Ngakhale zopatuka zing'onozing'ono zimayambitsa zosintha zokha, kuwonetsetsa kuti voliyumu ndi mawonekedwe abwino.

3. Njira Yophika

Mavuvuni oyendetsedwa ndi ma PLC amasunga kutentha kosasinthasintha ndikusintha kayendedwe ka mpweya.

Makina obwezeretsa mphamvu ophatikizidwa mumalingaliro a PLC amatha kuchepetsa kugwiritsa ntchito mafuta 20% .

4. Kuziziritsa ndi Slicing

PLC imagwirizanitsa kuthamanga kwa ma conveyor, mafani ozizira, ndi masamba ocheka kuti asunge kukhulupirika ndi ukhondo wazinthu.

Nthawi yodzichitira yokha imalepheretsa kukhazikika, kuwongolera moyo wa alumali.

5. Kukonzekera Kuneneratu

Ma analytics a PLC amazindikira mavalidwe azinthu ndi kutentha kwakanthawi koyambirira.

Othandizira amalandila zidziwitso kudzera pa mawonekedwe a HMI, kuchepetsa nthawi yopumira ndikukulitsa moyo wa zida.

Kuzindikira Katswiri - Udindo wa PLC mu Smart Bakery Manufacturing

Gulu la Katswiri: Andrew Ma Fu R&D department

-

Q: Chifukwa chiyani kuphatikiza kwa PLC kuli kofunikira kwa ophika buledi mafakitale?

A: Ma PLC amalumikiza njira iliyonse - kusakaniza, kutsimikizira, kuphika, ndi kuziziritsa - kukhala netiweki imodzi yanzeru.

Izi zimathandizira kukhazikika, kusinthika mwachangu, ndikuwongolera njira zolondola ngakhale ndi maphikidwe osiyanasiyana.

-

Q: Kodi ma PLC amathandizira bwanji kukhazikika?

A: Kudzera mu njira zoyendetsera mphamvu zamagetsi, ma PLC amachepetsa kutentha kosafunikira ndikubwezeretsanso kutentha kwa zinyalala, kupulumutsa mphamvu ndi mpweya.

-

Q: Ndi maubwino ati omwe machitidwe a PLC amapereka?

A: Mtundu uliwonse wa batch - kutentha, chinyezi, nthawi yophika - imasungidwa ndi kufufuza.

Izi zimathandizira Zotsatira za HACCP ndi ISO 22000 kutsata powonetsetsa kuti zinthu zonse zikuyenda bwino.

-

Q: Kodi machitidwe a PLC angasinthire luso lazogulitsa?

A: Inde. Othandizira amatha kusintha maphikidwe mosavuta pogwiritsa ntchito ma HMI a touchscreen. Zatsopano zitha kuyambitsidwa popanda kukonzanso mzere wonse.

-

Q: Kodi kusinthika kwina kwa PLC mu makina opangira buledi ndi chiyani?

A: Kuphatikiza ndi AI ndi makina masomphenya zidzathandiza kuwunika kwanthawi yeniyeni - kuzindikira zolakwika za mkate kapena mitundu yosiyana nthawi yomweyo.

Mafunso Ofunsidwa Kawirikawiri (FAQ)

-

Q: Ndi mitundu iti ya PLC yomwe imakondedwa pamakina ophika buledi?

A: Siemens, Allen-Bradley, Mitsubishi, ndi Omron ndi omwe amagwiritsidwa ntchito kwambiri chifukwa chodalirika komanso ntchito zapadziko lonse lapansi.

-

Q: Kodi mzere wophika buledi wodziwikiratu ukhoza kusinthidwa kukhala PLC control?

A: Inde. Ma module a PLC amatha kubweza makina akale, opereka zodzipangira okha popanda kumanganso kwathunthu.

-

Q: Kodi PLC imathandizira bwanji mphamvu zamagetsi?

A: Poyang'anira madera otentha, mafani, ndi ma mota motengera mayankho a sensa, kuchepetsa kugwiritsa ntchito mphamvu zopanda ntchito.

-

Q: Kodi makina a PLC ndi oyenera kuphika buledi ang'onoang'ono?

A: Mwamtheradi. Compact PLCs imatha kuyendetsa magwiridwe antchito ang'onoang'ono okhala ndi mawonekedwe osavuta amapulogalamu.

-

Q: Kodi PLC imawonetsetsa bwanji kuti chakudya chikutsatira chitetezo?

A: Kudula mitengo kumapereka kutsatiridwa kwathunthu kwa gulu lililonse lopanga, ndikofunikira kuti mukwaniritse malamulo achitetezo cha chakudya padziko lonse lapansi.

-

Q: Kodi ogwira ntchito angayang'anire dongosolo lakutali?

A: Inde. Ma PLC amalumikizana ndi ma dashboards amtambo kudzera pama protocol otetezedwa ngati Modbus-TCP kapena Ethernet/IP.

-

Q: Ndi kukonza kotani komwe kumafunikira ma PLC?

A: Zochepa - makamaka zosintha zamapulogalamu ndikusintha kwa sensor pachaka kuti zikhale zolondola.

Maupangiri & Magwero (ndi maulalo)

-

Automating Industrial Bakery Production Lines - Naegele Inc. Whitepaper

-

Chowdhury J.I. ndi al., Njira Zophatikizira Zophatikiza Kutentha kwa Zinyalala za Mavuni Ophika Ophika Ogulitsa, Elsevier (2023)

-

Zakudya Zosapanga zitsulo: 304 vs 316, AZoM (2023)

-

AI, ML & Data: Automation Revolutionizing Bakery & Snacks, BakeryAndSnacks (2024)

-

Modular Batch Control for Industrial Bakery PLC Systems, Siemens White Paper (2022)

-

Sustainable Automation mu Food Processing Industries, FoodTech Insight (2024)