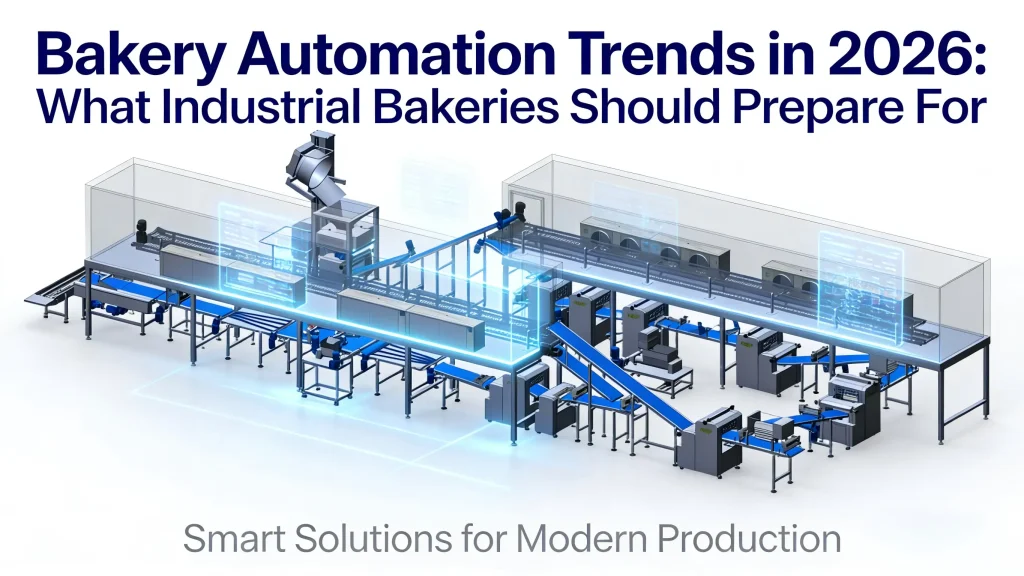

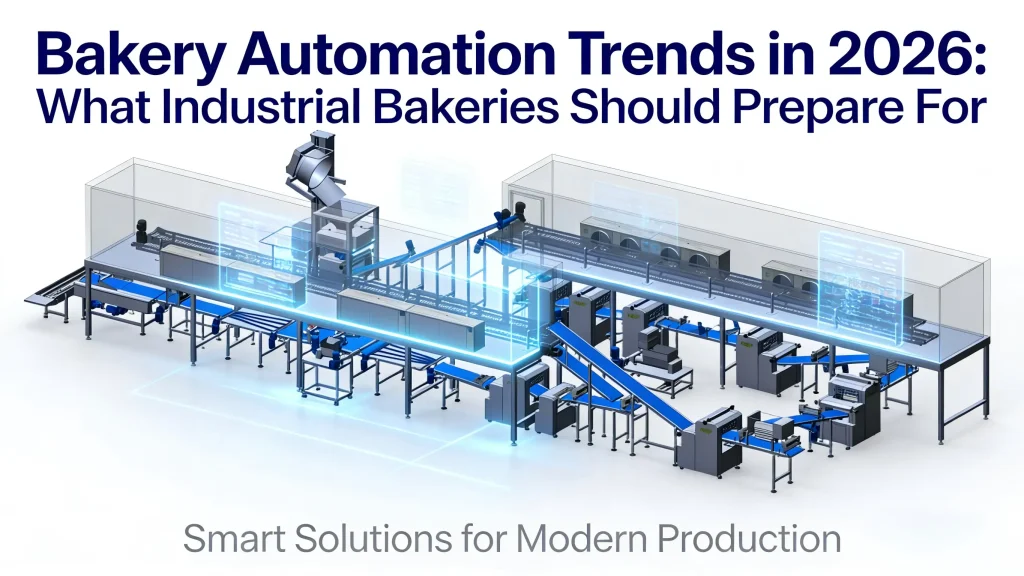

As the global bakery industry enters 2026, automation continues to play an increasingly critical role in shaping how industrial bakeries operate, scale, and compete. Rising labor costs, growing demand for consistent product quality, and stricter food safety standards are pushing manufacturers worldwide to rethink traditional production models and accelerate their transition toward automated bakery production lines.

At Andrew Mafu Machinery, we have observed clear changes in customer inquiries, production requirements, and project planning over the past year. These changes reveal several key trends that industrial bakeries should prepare for in 2026.

Automation Becomes a Strategic Necessity, Not an Option

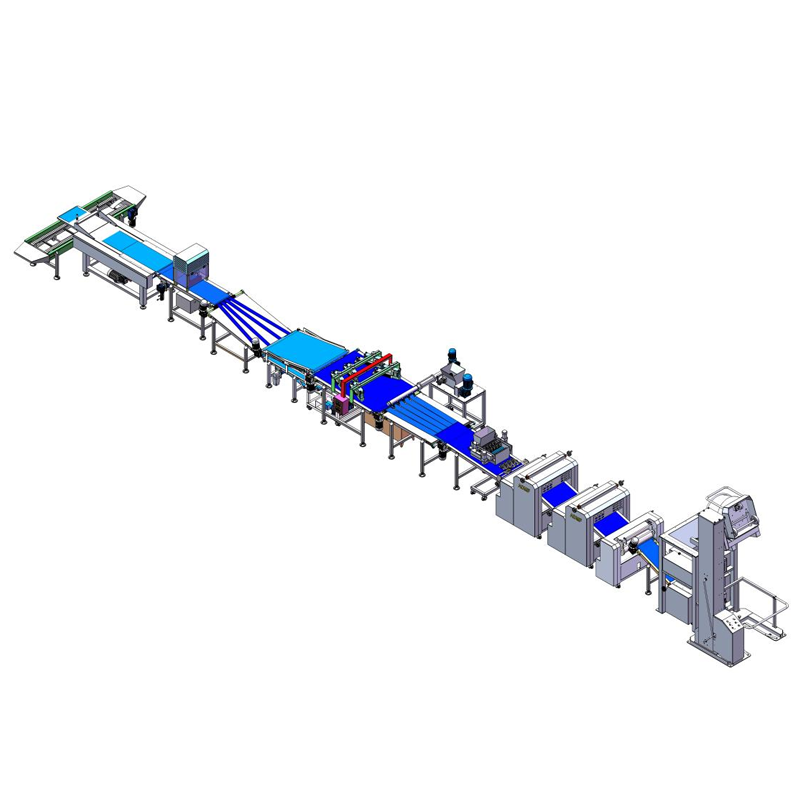

In previous years, automation was often viewed as a long-term upgrade plan. In 2026, it is becoming a strategic necessity. Many bakeries are facing persistent labor shortages, higher operational costs, and increased production pressure. Automated bread production lines help address these challenges by reducing manual dependency while maintaining stable output.

Industrial bakeries are no longer asking whether to automate, but how fast ma le to what level automation should be implemented. From dough handling and forming to tray arrangement and production flow control, automation is now integrated across entire production lines rather than isolated processes.

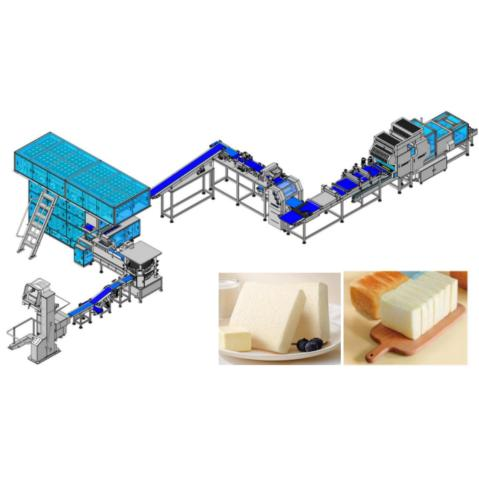

Higher Demand for Consistency and Product Standardization

Consistency has become a decisive competitive factor in global bakery markets. Retail chains, frozen food suppliers, and export-oriented producers require uniform size, weight, and appearance across large production volumes.

In 2026, automated bakery equipment is increasingly expected to deliver:

Advanced control systems and well-designed mechanical structures are essential to achieving these goals. Automated bread production lines are now designed with tighter tolerances and more precise synchronization to meet industrial consistency requirements.

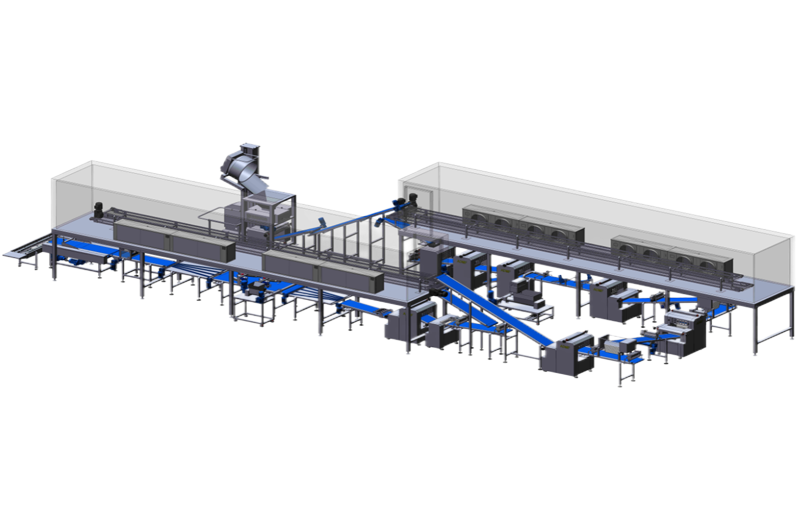

Production Lines Designed for Flexibility and Expansion

Another noticeable trend is the demand for flexible and scalable production lines. Many bakeries plan capacity expansion in stages rather than investing in a single large-scale project. As a result, modular design has become a key consideration in equipment selection.

In 2026, industrial bakeries prefer production lines that allow:

Andrew Mafu Machinery continues to develop modular solutions that allow customers to expand automation step by step while protecting their initial investment.

PLC Control Systems Drive Smarter Production

Modern bakery automation relies heavily on advanced PLC control systems. In 2026, control systems are no longer limited to basic start-stop functions. Instead, they play a central role in coordinating production flow, monitoring equipment performance, and maintaining process stability.

Well-designed PLC systems enable:

-

Precise synchronization between forming, conveying, and tray handling

-

Stable production rhythm at higher speeds

-

Reduced downtime through fault monitoring

-

Improved operator control and adjustment

As production lines become more complex, control system reliability and engineering experience become critical factors for long-term operation.

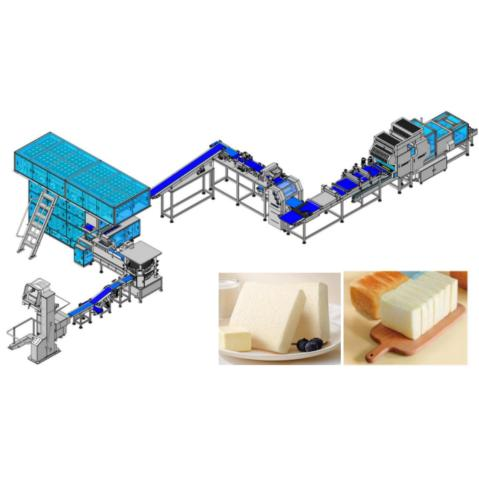

Consumer preferences continue to evolve toward softer bread textures, high-hydration dough products, and premium bakery items. These trends create new technical challenges for industrial bakeries, particularly in dough handling and forming stability.

In 2026, bakeries increasingly require equipment capable of handling:

-

High-hydration toast dough

-

Soft sandwich bread dough

-

Laminated pastry structures

-

Delicate dough shaping processes

Automated production lines must be designed with careful consideration of dough behavior, forming pressure, and transfer stability to ensure consistent output without damaging product structure.

Integration of Tray Handling and Auxiliary Automation

Tray handling is becoming a critical bottleneck in many bakeries. Manual tray arrangement not only limits production speed but also introduces inconsistencies and hygiene risks. As a result, tray arrangement systems are increasingly integrated directly into automated bread production lines.

In 2026, bakeries are investing more in:

-

Automatic trays arrangement machines

-

Conveyor-based tray transfer systems

-

Integrated forming-to-tray workflows

This integration improves overall line efficiency and allows bakeries to maximize the benefits of full-line automation.

Global Standards and Food Safety Compliance

Food safety regulations continue to tighten across global markets. Industrial bakeries exporting to multiple regions must comply with international hygiene standards, material requirements, and production traceability expectations.

Automated bakery equipment in 2026 must support:

-

Hygienic design principles

-

Easy cleaning and maintenance

-

Food-grade materials and components

-

Stable long-term operation

Manufacturers with strong engineering standards and quality control systems are better positioned to support customers operating in regulated markets.

Andrew Mafu Machinery’s Perspective on 2026

Based on ongoing cooperation with global customers, Andrew Mafu Machinery believes that successful bakery automation in 2026 will be built on three core principles:

-

Engineering-driven design rather than generic equipment solutions

-

Scalable automation that supports long-term growth

-

Stable and reliable performance under continuous industrial operation

By focusing on these principles, bakeries can improve efficiency, reduce operational risk, and remain competitive in evolving markets.

Looking Forward: Preparing for the Year Ahead

As 2026 unfolds, industrial bakeries that invest in automation thoughtfully and strategically will be better positioned to handle market fluctuations, labor challenges, and rising quality expectations.

Andrew Mafu Machinery remains committed to supporting bakery manufacturers with practical automation solutions, technical expertise, and long-term cooperation. Through continuous innovation and close collaboration with customers, the company looks forward to contributing to a more efficient and automated global bakery industry in the year ahead.

FAQ – Bakery Automation Trends in 2026

1. Why is full-line bakery automation becoming more common in 2026?

Rising labor costs, workforce shortages, and higher production consistency requirements are driving bakeries to adopt full-line automation instead of isolated machines. Automated bread production lines allow better control over output, hygiene, and long-term operating costs.

2. How do PLC control systems improve bakery production efficiency?

PLC systems synchronize forming, conveying, and auxiliary equipment, ensuring stable production rhythm, accurate timing, and reduced downtime. Advanced PLC control also supports fault monitoring and parameter optimization during continuous operation.

3. What types of bakeries benefit most from automated production lines?

Industrial bakeries producing bread, toast, sandwich bread, and frozen bakery products benefit most, especially those serving retail chains, export markets, or high-volume food service clients.

4. Can automated bread production lines handle high-hydration dough?

Yes. Modern production lines are increasingly designed to handle high-hydration and soft dough through optimized forming structures, controlled pressure, and stable transfer systems.

5. How important is tray handling automation in modern bakeries?

Tray handling is often a bottleneck in production. Automated tray arrangement and transfer systems significantly improve line efficiency, reduce manual labor, and enhance hygiene standards.

6. Is modular design important when planning bakery automation in 2026?

Very important. Modular production lines allow bakeries to expand capacity gradually, adapt to new products, and integrate additional automation without replacing the entire line.

7. What should bakeries consider when selecting an automation equipment supplier?

Key factors include engineering experience, system stability, customization capability, long-term service support, and proven industry references rather than only machine price.

Faamatalaga & Punavai

- Auala e Filifili ai le Port Alamanuia masini mo lau falesa,Lenexa Manufacturing, 2022.

- Ototototogi a le au fai pisinisi,Naegele Inc.Whitepaper.

- Sauni e otometi lau pashry gaosiga laina?,EZASOL Inc., 2023.

- E faʻafefea ona suia e le otometi ona suia le vaʻai o le falaoa,Bake Magazine, December 2022.

- Laʻau Gaidy Land Laasaga: Faʻamalosi lau meaʻai ma le maualuga-lelei meafaigaluega,Gaux Blog, February 2025.