Automatic bread production line is a fully or semi-automated system designed to produce bread on a large scale. It integrates various machines and processes, such as mixing, dividing, shaping, proofing, baking, cooling, and packaging, to streamline bread production with minimal human intervention.

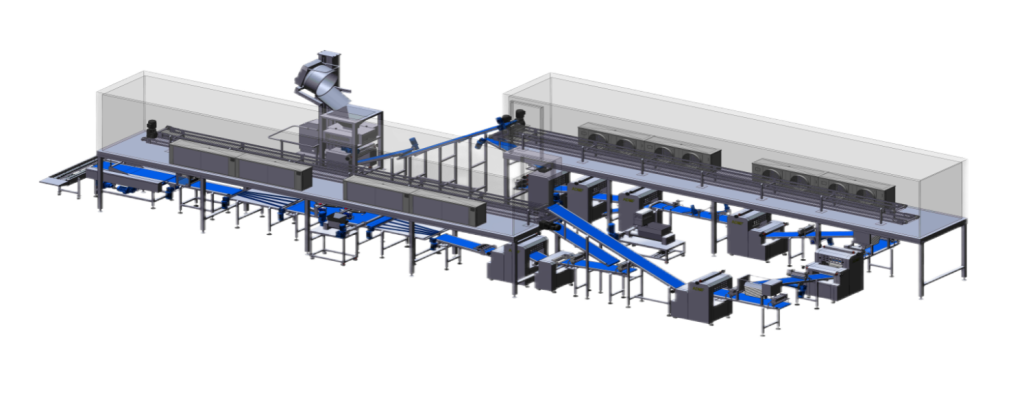

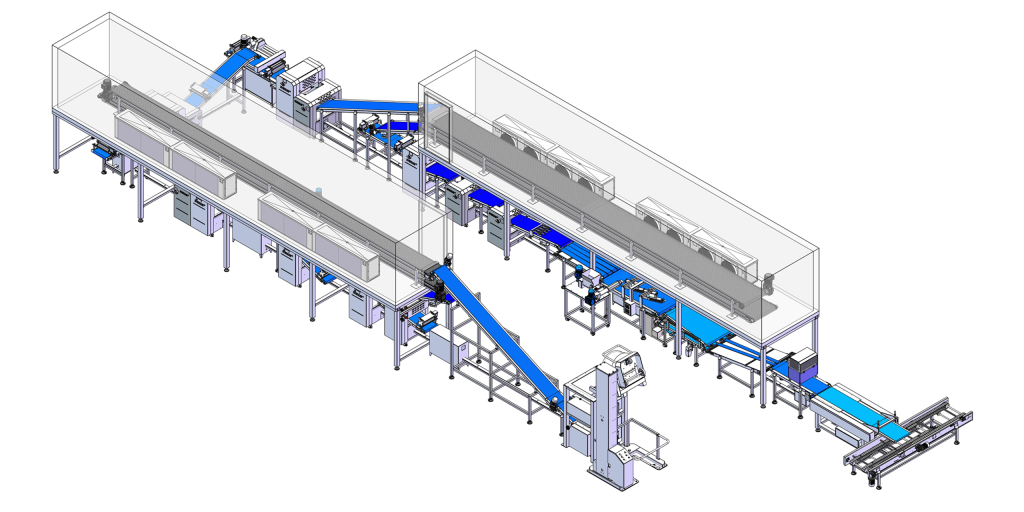

MODEL | ADMF-400-800 |

MACHINE SIZE | L21M*7M*3.4M |

CAPACITY | 1-2T/HOUR(Adjustable according to customer requirements) |

TOTAL POWER | 82.37KW |

An automatic bread production line is a highly integrated system where each stage of the bread-making process is automated. The key stages include dough preparation, fermentation, shaping, proofing, baking, cooling, and packaging.

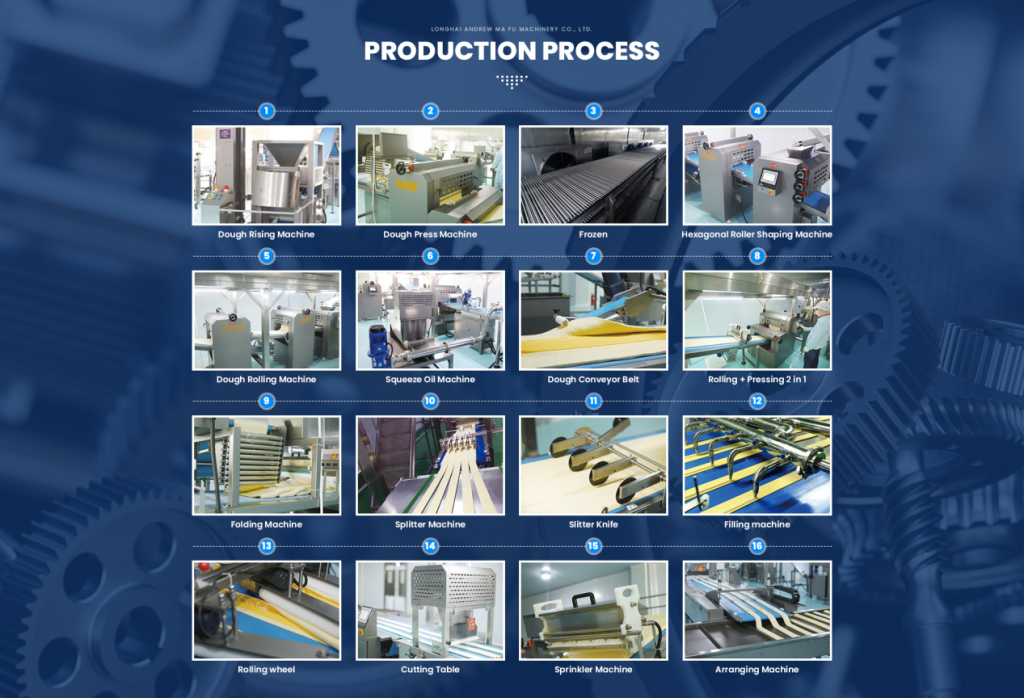

Material→02. Mixing(15-18mins)→03. Forming(50mins)→04. Dough awakening(15-3hrs)05.→05. Baking(15-18mins)→06. Depanner→07. Cooling(20-25mins)→08. Packing machine(1 to 5)

1. The dough is rolled and extended by several pressing wheels and defending devices to make the doughmore glossy and stable in quality.

2. Each pressing wheel is equipped with a thickness adjustment device to set the thickness of the crust toincrease or decrease the weight of the product.

3. The speed of the dough is controlled by the electric service between the dough roller and the thinningdevice, so that the dough won't be broken or blocked if the conveyor speed is too fast or too slow.

4. After the last pressing wheel of the main machine, the dough will fall on the conveyor belt of the main machine, and then the dough will be rolled into strips by the rollers and auxiliary rollers.

5. lf you want to produce cut products, you can open the separate cutting table and set the cutting length todetermine the length and weight of the products.

6. With synchronized speed control function, operation is more convenient.

A fully automatic bread production line can be used to produce a wide variety of breads, such as:

Soft, fluffy bread made from refined wheat flour.

Bread made from whole wheat flour, typically denser than white bread.

Made from rye flour, often with a denser, more compact texture.

Bread made from a combination of grains like oats, barley, and millet, along with wheat.

Long, narrow loaves with a crisp crust and light, airy texture inside.

Smaller, individual portions of bread.

We work fast. With the increasing number of customers approaching us, we have no other option but to prioritize speed. Let’s look at the whole process of manufacturing and shipping:

Large bakeries use these lines to produce massive quantities of bread daily, ensuring efficiency and consistency in every batch.

Industrial bread manufacturers, especially those that supply supermarkets and retailers, rely on automatic production lines for high-volume bread production.

Some production lines are adapted to produce frozen bread, which can be stored and sold later.

Automatic lines can be customized for the production of artisan breads, baguettes, and other specialty products, ensuring high quality with precision.

Automatic bread production lines can produce a wide variety of bread types, including:

Sliced bread (white, whole wheat, multigrain)

Buns and rolls

Baguettes

Artisan bread

Frozen dough products

Specialty bread (e.g., gluten-free, low-carb)

High-speed production: Can produce thousands of loaves per hour.

Consistency: Ensures uniform size, shape, and quality.

Labor savings: Reduces the need for manual labor.

Reduced waste: Precise control minimizes ingredient and product waste.

24/7 operation: Can run continuously with minimal downtime.

Production capacity varies depending on the equipment and scale. Small lines may produce 500–1,000 loaves per hour, while large industrial lines can produce 5,000–10,000 loaves per hour or more.

Space requirements depend on the scale of the production line. A small line may require 500–1,000 square meters, while a large industrial line may need 2,000–5,000 square meters or more. Proper layout planning is essential to optimize workflow.

Regular maintenance is crucial to ensure smooth operation and longevity. Key maintenance tasks include:

Cleaning and sanitizing equipment

Lubricating moving parts

Inspecting and replacing worn-out components

Calibrating sensors and control systems

Yes, production lines can be customized to meet specific needs, such as:

Producing different types of bread

Adjusting production capacity

Incorporating additional features (e.g., gluten-free or organic production)

Integrating with existing equipment

Setup time depends on the complexity of the line and the availability of infrastructure. It can range from a few weeks for a small line to several months for a large, fully automated line.

Increased production efficiency

Consistent product quality

Reduced labor costs

Improved hygiene and food safety

Scalability for growing demand

High initial investment cost

Requires skilled technicians for operation and maintenance

Limited flexibility for small-batch or artisanal production

Dependence on reliable power and water supply

Yes, many production lines can be adapted for gluten-free or specialty bread. However, additional precautions are needed to avoid cross-contamination, such as dedicated equipment or thorough cleaning between batches.

The control system (e.g., PLC or computer-based) monitors and controls the entire production process, ensuring:

Precise timing and temperature control

Consistent product quality

Real-time monitoring and troubleshooting

Data collection for process optimization

Yes, many production lines can be upgraded with additional equipment or modifications to increase capacity or add new product lines. Consult with your equipment supplier for tailored solutions.

Operators and technicians need training on:

Equipment operation and maintenance

Food safety and hygiene practices

Troubleshooting and problem-solving

Quality control procedures