Contents

Andrew Ma Fu Machinery Import and Export Co., Ltd. (ADMF), a respected name in baking automation, today unveiled its latest innovation: the Dough Kneading Machine, a state-of-the-art solution designed to improve efficiency, consistency, and scalability across industrial and artisanal bakery operations.

For over 15 years, Andrew Ma Fu has specialized in baking machinery, evolving from basic mixers to comprehensive, automated production lines. Their offerings include automatic bread, croissant, and sandwich production lines, along with high-speed dough mixers, computer-controlled pastry machines, and other specialized units tailored to global bakery needs .

Manufactured within a 20,000-square-meter modern facility, ADMF backs its products with a large technical service team of over 100 professionals, reflecting a strong commitment to R&D, quality, and customer support .

While ADMF’s online catalog doesn’t list a stand-alone “Dough Kneading Machine,” the company prominently features high-speed horizontal dough mixing systems among their specialized equipment. These mixers form the backbone of many bakery automation setups by delivering consistent, well-developed dough at high throughput.

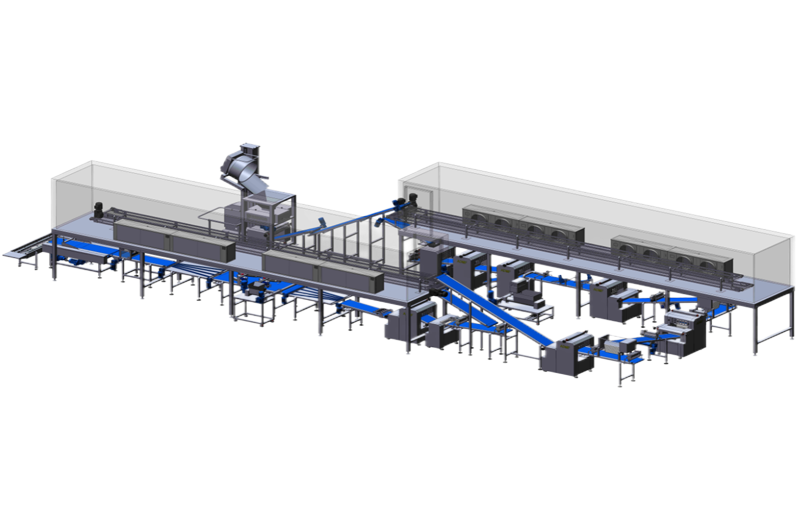

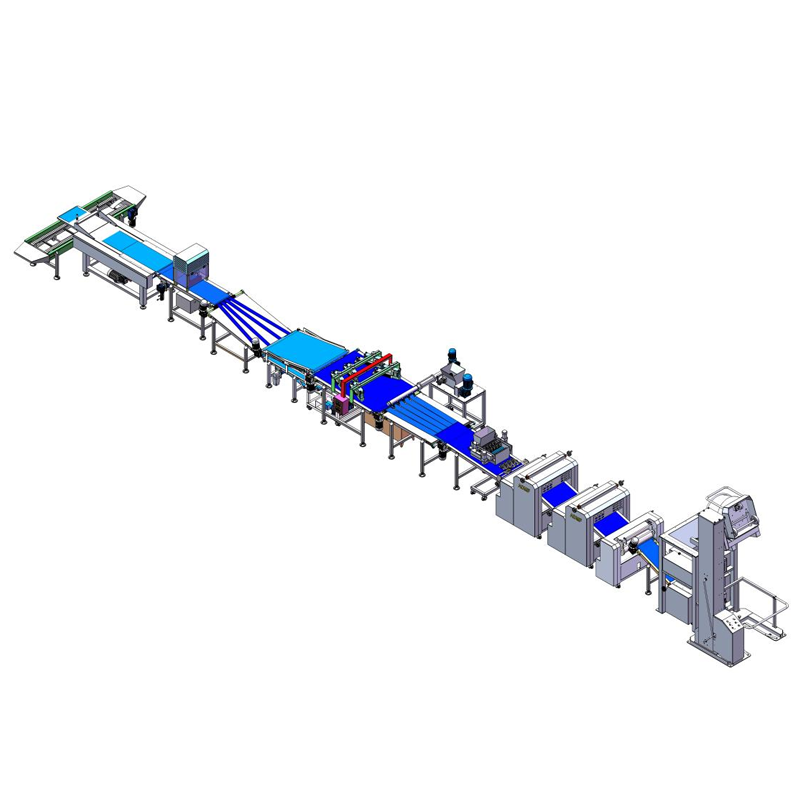

Such mixers are integral components of ADMF’s broader production lines—particularly the Simple Bread Production Line (ADMFLINE-002), where dough mixing, shaping, proofing, and baking are streamlined into a single automated sequence with outputs of 0.5–1 ton/hour and a total power consumption of 20 kW.

The dough kneading or mixing stage is critical to bakery production. In ADMF’s setups, dough mixes flow seamlessly from kneading into forming, proofing, and baking. This is evident in product lines such as:

Simple Bread Production Line (ADMFLINE-002): Tailored for small-to-medium bakeries, it automates key stages from mixing to baking with modular peripheral equipment, adjustable parameters, consistent product weight, and flexible functionality .

Croissant Production Line (ADMFLINE-001): Includes mixing, rolling, shaping, cutting, lamination, and baking stages, capable of producing between 4,800 to 48,000 pieces per hour with a 20 kW power rating—highlighting how dough kneading integrates fluidly into pastry workflows.

High Throughput & Consistency

ADMF’s kneading units are built for speed and precision, setting the stage for large-scale bakery productivity while maintaining uniform dough quality.

Modular & Customizable Design

Designed for flexibility, their systems allow ingredient formulations, thickness, weight, and shapes to be tailored to client specifications.

Simplified Operation & Cleanability

Leveraging stainless steel construction and user-friendly modular interfaces, ADMF’s machinery ensures both operator convenience and compliance with hygiene standards.

Energy Efficiency & Cost Control

With optimized power consumption—typically around 20 kW for lines including kneading, forming, and baking—ADMF’s systems balance performance with savings.

End-to-End Support

ADMF offers one-stop solutions—from pre-sale design to installation and training—making it easier for bakeries to deploy production lines efficiently and reliably.

ADMF operates within a vertically integrated industrial cluster in Longhai District, Zhangzhou, linking equipment manufacturing, upstream/downstream material suppliers, and an R&D center. This synergy allows rapid customization and response to client demands.

This model has already attracted international attention—most recently from clients in the Philippines exploring ADMF’s kneading and forming production lines. They praised the factory layout and precision engineering, emphasizing the appeal of quick adaptation, robust after-sales support, and local ingredient compatibility.

Andrew Ma Fu’s machinery is trusted across more than 120 countries and regions, serving over 100 domestic and international clients.

Looking forward, ADMF is committed to advancing digital, green, and intelligent technologies in baking automation. Their roadmap includes deeper R&D investment, broader product innovation, and deeper global market penetration under principles of “innovation, quality, and responsibility”.

Though not spotlighted in isolation, ADMF’s Dough Kneading Machine—most likely embodied in their high-speed mixers—forms the operational cornerstone of their automated bakery offerings. Through its seamless integration, modular design, energy efficiency, and global support network, it empowers bakeries to scale production without sacrificing quality or flexibility.

As bakeries worldwide seek reliable, efficient dough processing, Andrew Ma Fu’s kneading technology—backed by innovation, cluster synergy, and a global vision—stands ready to elevate industry standards.

Previous News

Andrew Ma Fu Unveils High-Speed ADMF Bread Toas...Next News

Andrew Mafu Machinery Wishes You a Happy Mid-Au...

By ADMF

Croissant Production Line: High Efficiency an...

The automatic bread production line is a full...

Efficient Automatic Bread Production Lines fo...