Andrew Mafu Baking Machinery Emerges as Breakout Star at Bakery China 2025 with Advanced Automation Solutions

The cavernous halls of Shanghai’s National Exhibition and Convention Center (NECC) witnessed a new titan rise in industrial baking this week as Andrew Mafu Baking Machinery captivated attendees at Bakery China 2025. Running from May 19-22 at the sprawling 330,000 sqm venue, the world’s largest baking industry exhibition hosted 2200+ exhibitors and 400,000+ professional visitors from 130+ countries . Against this backdrop of fierce global competition, Andrew Mafu’s technologically advanced production lines—including its revolutionary croissant forming, hamburger bun, and high-moisture bread systems—drew sustained crowds and earned unanimous acclaim from industrial bakers, QSR suppliers, and industry veterans alike.

The Global Stage: Bakery China’s Unrivaled Scale

Organized by the China Bakery and Confectionery Industry Association, Bakery China has evolved since 1997 into the Asia-Pacific’s definitive baking technology showcase. The 2025 edition shattered records, featuring dedicated zones spanning ingredients, packaging, retail solutions, and heavy machinery. Notably, over 20% of exhibitors represented global baking powerhouses like Germany, Italy, and Japan , setting a high bar for innovation. Andrew Mafu’s strategic positioning within the machinery pavilion allowed its solutions to shine before a concentrated audience of high-value buyers—including multinational frozen dough producers and artisanal bakery chains seeking scalable automation.

Engineering Marvels: The Technology Behind the Acclaim

1. Croissant Forming Production Line: Precision at Industrial Scale

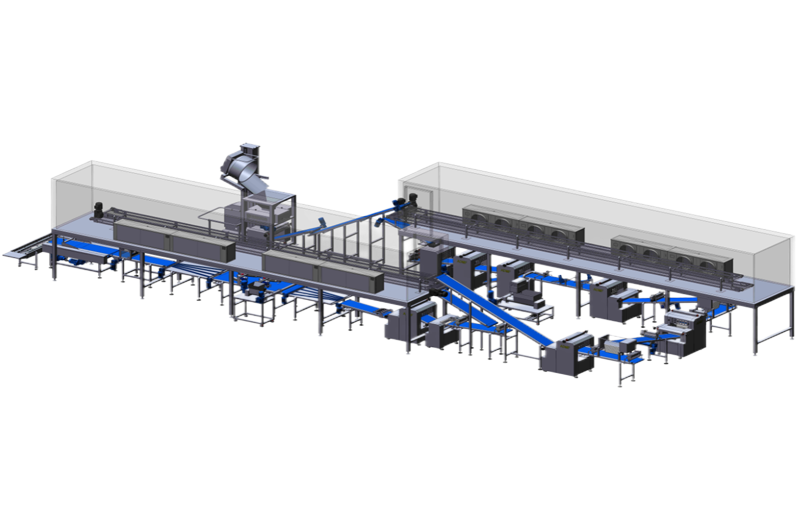

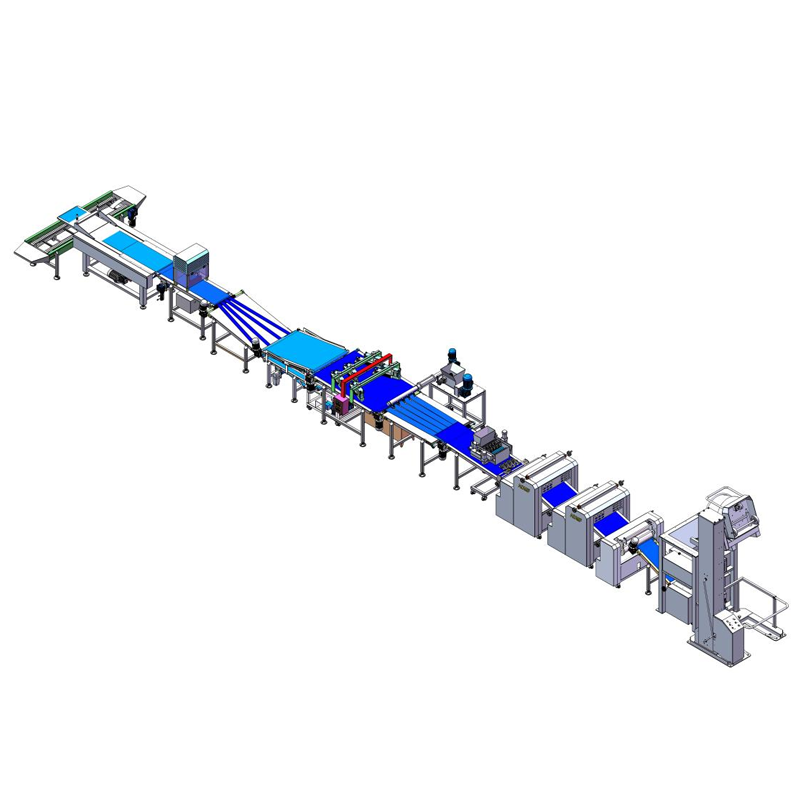

Andrew Mafu’s fully automated croissant system became an instant magnet for European and Asian patisserie manufacturers. The line integrated dough sheeting, precision butter lamination, shaping, and proofing into a single continuous operation, achieving a staggering output of 12,000 perfectly layered croissants per hour. Demonstrations highlighted its ability to handle high-butterfat formulations without temperature compromise—a critical pain point for mass producers. “This solves our twin nightmares: labor inconsistency and seasonal butter performance issues,” remarked Zhang Wei, Production Manager of a major Chinese bakery chain, after witnessing the system’s flawless lamination integrity .

2. Hamburger Forming Production Line: Flexibility for the QSR Boom

Designed to capture Asia’s exploding quick-service restaurant market, Andrew Mafu’s hamburger bun line showcased unprecedented agility. Its modular design enabled sub-3-minute changeovers between standard buns, brioche rolls, seeded varieties, and artisan-style ciabatta carriers. Proprietary dough-division technology guaranteed weight accuracy within 0.5 grams—critical for QSR cost control. “We supply three global burger chains,” noted Indonesian frozen dough producer Arif Santoso. “This eliminates ‘giveaway’ weight while maintaining structural integrity through freezing and toasting cycles—it’s a game-changer.”

3. High-Moisture Bread Production Line: Artisan Quality, Industrial Output

Perhaps the most technically significant reveal was Andrew Mafu’s high-moisture bread system, engineered specifically for Asia’s booming artisan-style bread market. Capable of handling dough hydration levels up to 60-80%, the line incorporated specialized low-stress extruders and fermentation-controlled conveyors to preserve delicate crumb structures in breads like Japanese milk bread and ciabatta. Japanese baking engineer Kenji Tanaka noted, “Finally, automation that respects gluten development rather than destroying it. Their dough-handling philosophy mirrors skilled artisans’ techniques.”

Market-Driven Engineering: The Secret to Industry Validation

Beyond mechanical innovation, Andrew Mafu’s triumph stemmed from 18 months of intensive field research across Asian bakeries. Recognizing that European machinery often failed to address regional challenges—such as handling low-protein flours or tropical climate conditions—the company engineered solutions tailored to local production realities. “Too many European makers assume one-size-fits-all,” observed Chen Li, Technical Director of Shanghai’s Sunrise Bakeries. “Andrew Mafu’s engineers studied our pain points onsite. Their systems feel bespoke despite being standardized platforms” .

This customer-centric approach was amplified by live demonstrations using region-specific ingredients, from high-moisture Asian flours to sticky fruit fillings. Technical teams—including master bakers alongside engineers—provided nuanced consultations on fermentation management and energy efficiency, transforming standard sales pitches into collaborative problem-solving sessions.

Industry Accolades and Commercial Impact

The acclaim transcended audience admiration: On May 20, Bakery China’s organizing committee awarded Andrew Mafu’s high-moisture line a “Top 10 Baking Innovation” prize, citing its potential to reduce waste through optimized baking protocols . Simultaneously, three multinational ingredient suppliers—including a leading European yeast producer—initiated talks to integrate their products into Andrew Mafu’s testing labs for official compatibility certification.

Commercial results were immediate: By the exhibition’s close, Andrew Mafu reported 120+ serious inquiries and 23 provisional agreements for equipment trials across China, Southeast Asia, and Australia. In a strategic move underscoring long-term commitment, the company announced a Shanghai-based technical center to open by Q4 2025—positioning itself at the epicenter of Asia’s baking industry growth .

The Future of Intelligent Baking Automation

As Bakery China 2025 concluded, industry analysts highlighted how Andrew Mafu’s solutions aligned with the event’s core themes: automation resilience amid labor shortages, demand for premium-at-scale products, and energy efficiency imperatives. “The conversation has shifted from pure output volume to intelligent output,” noted Grace Wang of FoodTech Consulting Asia. “Andrew Mafu demonstrated precision, flexibility, and product integrity—the trifecta modern bakers need.”

David Chen, Andrew Mafu’s CEO, reflected while overseeing booth dismantling: “The validation here confirms our R&D direction. We’re not just selling machines; we’re building partnerships to redefine automated baking.” With competitors already dissecting their innovations, Andrew Mafu’s Shanghai showcase may well be remembered as the moment industrial baking’s balance of power tilted toward intelligent, adaptable automation—where engineering finally honors the craft.

For more information about Andrew Mafu’s product portfolio, please visit www.andrewmafugroup.com.

Previous News

Andrew Mafu Machinery Showcases Innovative Brea...Next News

Andrew Mafu Machinery Showcases Cutting-Edge Ba...

By ADMF

Croissant Production Line: High Efficiency an...

The automatic bread production line is a full...

Efficient Automatic Bread Production Lines fo...