Russian Agent Visits Andrew Mafu Machinery, Signals Long-Term Partnership on Bakery Production Lines

In a promising step toward strengthening international cooperation in the bakery equipment sector, a prominent Russian agent recently visited the headquarters and manufacturing facility of Andrew Mafu Machinery. The primary purpose of the visit was to evaluate the company’s advanced baking solutions — notably the croissant forming production line, hamburger forming production line, and high-moisture bread production line — with the goal of forming a long-term strategic partnership.

The visit concluded with fruitful discussions and mutual agreement on establishing a long-term cooperation plan between the two parties. This development underscores Andrew Mafu Machinery’s growing role as a leading global supplier of automated bakery production technology.

Contents

Upon arrival, the Russian agent was welcomed by Andrew Mafu’s international business team and escorted on a comprehensive factory tour. The visit began with a presentation highlighting the company’s core capabilities, innovation strategies, and successful project cases across more than 30 countries.

The Russian guest was especially interested in high-capacity automated production lines that can meet growing demand in Eastern Europe for industrial-scale bakery products. With the Russian market experiencing a rapid transformation in food manufacturing standards and consumer preferences, the agent’s objective was clear: to source efficient, intelligent, and reliable machinery capable of producing high-quality baked goods.

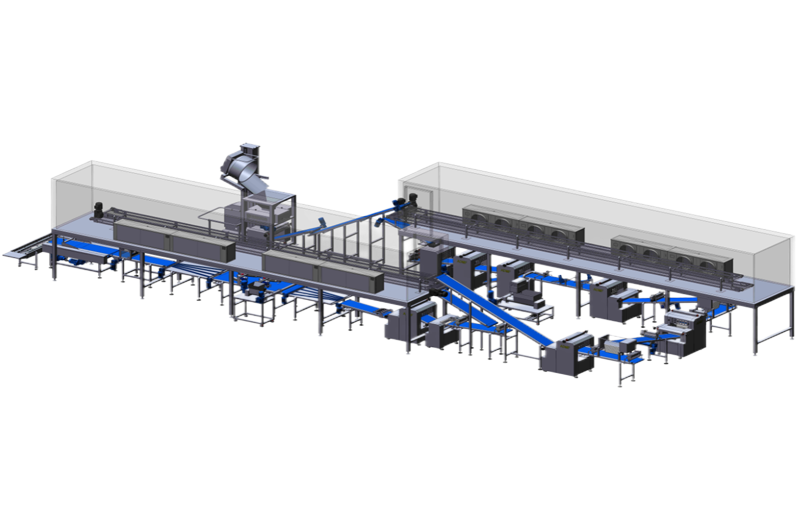

The croissant forming production line was one of the primary attractions during the visit. Andrew Mafu’s croissant line integrates dough sheeting, butter layering (lamination), cutting, and automatic curling in a seamless and fully automated process. The line delivers high output while maintaining artisanal croissant characteristics such as even layers, precise shape, and consistent size.

The Russian agent observed a live demonstration of the line in operation and took particular note of its flexibility to produce various croissant styles, including plain, filled, and mini croissants.

“This is the kind of equipment the Russian market is looking for,” the agent commented. “Automation is key, but it must not sacrifice the product’s quality. The croissant forming production line at Andrew Mafu meets both criteria.”

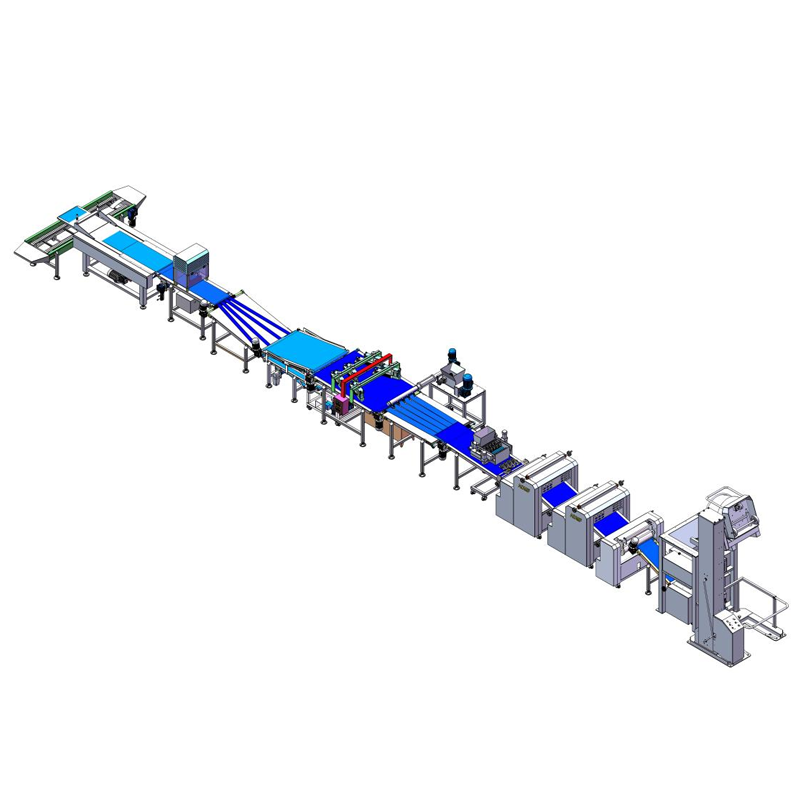

Following the croissant demonstration, the Russian visitor was introduced to the hamburger forming production line, a system known for its precision, speed, and uniform output. The line features dough dividers, rounders, and molders, all integrated into a smart control system that ensures minimal waste and maximum productivity.

With demand for Western-style fast food and sandwich buns growing across Russia and neighboring countries, the agent expressed great interest in this line for its potential to support large-scale bakery operations.

“What impressed me is how the hamburger bun forming system ensures consistent softness and shape,” the agent said. “This would be ideal for commercial bakeries supplying major restaurant chains or retail markets.”

The high-moisture bread production line proved to be a technological highlight of the visit. Designed for the production of soft, long-lasting, and nutritious bread loaves, this system uses advanced hydration technology, gentle kneading, and extended proofing to retain internal moisture and deliver superior texture.

The Russian agent sampled fresh bread produced by the line and praised its structure, taste, and shelf-life potential. Such bread products are increasingly popular among Russian consumers who favor quality and natural ingredients over preservatives.

“This high-moisture bread production line represents a new level of bread-making,” the agent observed. “It offers both health benefits and longer freshness, which align with current trends in the Russian market.”

Beyond demonstrations, the Russian agent engaged in in-depth technical discussions with Andrew Mafu’s engineers and R&D specialists. Topics included production line capacity planning, recipe compatibility, utility consumption, and machine customization for Russian standards (such as voltage requirements and language support in the user interface).

The Andrew Mafu team shared past experiences in customizing systems for overseas clients and emphasized their ability to provide full lifecycle support — from design and manufacturing to installation, training, and after-sales service.

The Russian agent expressed confidence in Andrew Mafu’s ability to deliver tailored solutions:

“We don’t just need machines — we need partners who understand our market. Andrew Mafu has both the technology and the willingness to adapt it to our unique needs.”

As the visit came to a close, both sides expressed strong interest in forming a long-term cooperation. The Russian agent confirmed intentions to begin procurement planning for an initial set of bakery lines, with a view to scaling up installations across multiple factories in Russia over the next three years.

Mr. Liu Ming, Director of Global Sales at Andrew Mafu Machinery, welcomed the agreement:

“We are honored to establish a long-term relationship with our Russian partner. Our mission is to provide reliable, efficient, and intelligent bakery solutions to clients worldwide, and we believe this partnership will open new opportunities for both sides.”

Mr. Liu also emphasized the company’s commitment to quality and global service:

“Each machine is built with precision, tested rigorously, and supported by our multilingual service team. Whether it’s installation in Moscow or operator training in Siberia, we are ready to assist every step of the way.”

The visit and resulting agreement mark another milestone in Andrew Mafu Machinery’s expansion into international markets. The company’s equipment is now installed in commercial bakeries, food processing plants, and central kitchens across Asia, Europe, the Middle East, and South America.

Andrew Mafu’s reputation has been built on its ability to blend traditional bakery craftsmanship with advanced industrial automation. Its croissant forming production line, hamburger forming production line, and high-moisture bread production line continue to attract clients who seek efficiency without compromising product integrity.

With the successful conclusion of this visit and mutual intention for cooperation, the partnership between Andrew Mafu Machinery and its Russian counterpart is expected to pave the way for increased bakery innovation in Russia. Together, they aim to bring premium-quality baked products to more consumers while raising the standard for industrial bakery operations in Eastern Europe.

As global consumer demand evolves, such international collaborations will be essential to advancing the future of food production.

Contact Andrew Mafu Machinery

Tel/Wechat/WhatsApp: +86 18405986446

Email: [email protected]

Website: www.andrewmafugroup.com

Keywords: croissant forming production line, hamburger forming production line, high-moisture bread production line

Let me know if you’d like to include image placement tags or have this article optimized for a specific platform like a company website or trade magazine.

Previous News

Andrew Mafu Machinery Showcases Cutting-Edge Ba...Next News

Andrew Mafu Machinery Impresses International C...

By ADMF

Croissant Production Line: High Efficiency an...

The automatic bread production line is a full...

Efficient Automatic Bread Production Lines fo...