In an era where technology and tradition often collide, Andrew Mafu Machinery has found the perfect recipe for harmony.

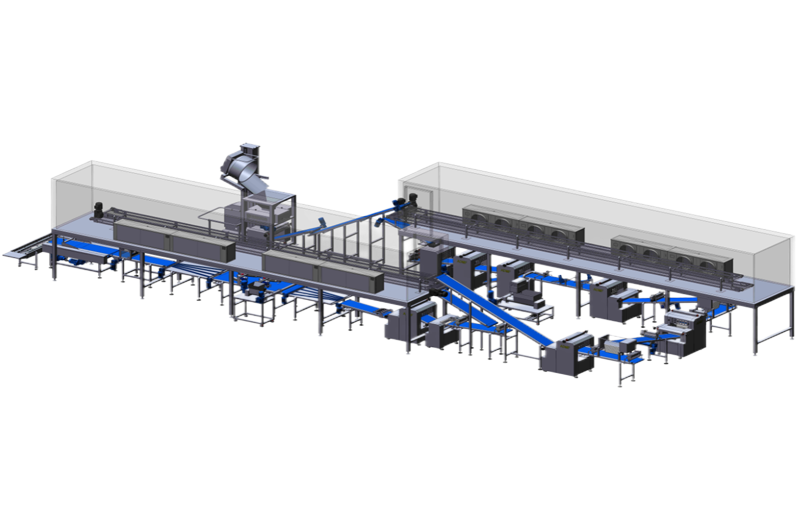

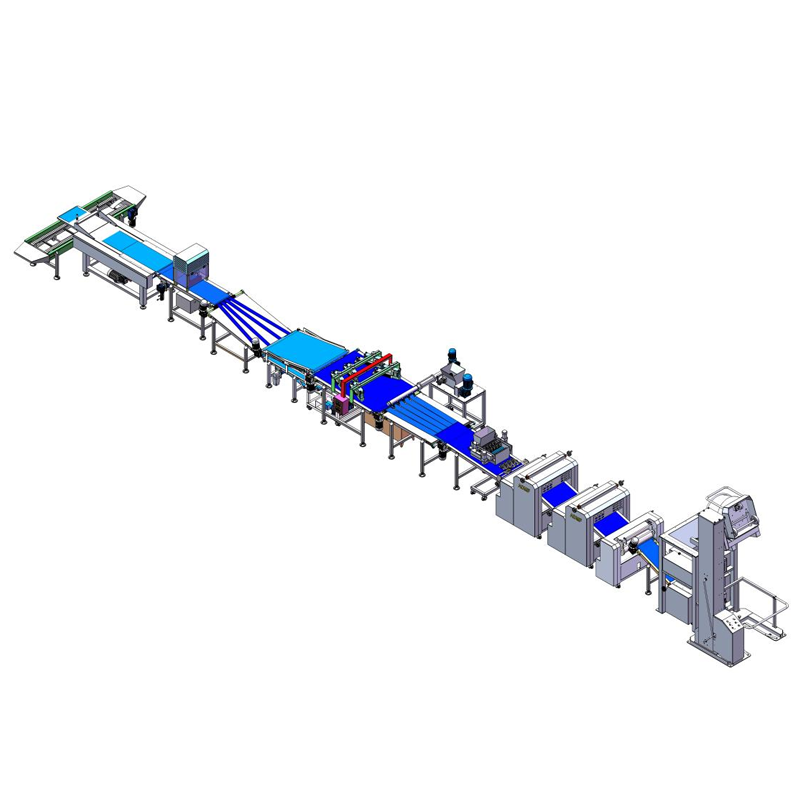

With the grand unveiling of their latest breakthrough—an Automated Bread Production Line—this innovative firm is taking the baking industry to unprecedented heights. Combining cutting-edge engineering with the warmth of artisanal craftsmanship, the newly launched system promises to revolutionize the way bread is produced, distributed, and enjoyed around the world.

Product Parameters:

| MODEL | ADMF-400-800 |

| MACHINE SIZE | L21M*7M*3.4M |

| CAPACITY | 1-2T/HOUR(Adjustable according to customer requirements) |

| TOTAL POWER | 82.37KW |

Founded with a mission to automate and elevate food production, Andrew Mafu Machinery has consistently introduced trailblazing technology to the industry. Their newest innovation, the bread forming production line, is the culmination of years of research, feedback from global bakeries, and relentless engineering.

AUTOMATIC BREAD PRODUCTION LINE

Unlike traditional equipment that relies heavily on manual oversight, Mafu’s bread forming production line is entirely automated—from dough handling to final packaging. It integrates sensors, AI-driven controls, and modular design elements for ultimate flexibility and speed.

The production line includes a high-speed horizontal dough mixer, a dough divider, proofing systems, advanced ovens, and a smart slicing and packaging machine. Every component communicates seamlessly with the central command unit, ensuring real-time performance analysis and adjustments.

Efficiency Meets Artistry

Though fully automated, Mafu’s system respects the craft of baking. The kneading process mimics human technique, and customizable settings allow bakeries to produce everything from rustic loaves to soft sandwich buns without compromising flavor.

Global Implications and Market Reach

Interest from Europe, North America, and Asia has skyrocketed. Bakeries around the world are looking to upgrade outdated systems with Mafu’s sleek, scalable solution.

Customer Success Stories

In Ghana, local bakery chain BreadRise saw production double within a month of installation, with a 30% reduction in labor costs. Similar success stories are emerging from Peru, Thailand, and Poland.

Mafu’s launch isn’t just about selling machines. It includes comprehensive training modules, virtual maintenance support, and 24/7 multilingual customer service to help bakers transition smoothly.

Economic Impact and Job Creation

While automation often raises concerns about job losses, Mafu’s system redefines roles instead. Operators now manage advanced systems, learn digital skills, and contribute more strategically to production.

Real-Time Monitoring and Smart Analytics

Every stage of the baking process is trackable. Performance metrics, ingredient efficiency, energy usage, and maintenance needs are visible on a central dashboard accessible remotely.

Adaptability Across Bakery Sizes

Whether a boutique patisserie or an industrial bread manufacturer, the line adapts to various scales. Its modular design means parts can be added or removed based on demand.

Breaking Barriers in Artisan Baking

Artisan bakers often shy away from automation due to quality concerns. Mafu’s bread forming production line is designed to replicate artisanal methods while offering the benefits of consistency and speed.

Partnerships and Collaborations

To scale globally, Andrew Mafu Machinery has partnered with logistics firms, universities, and international distributors to spread knowledge and access.

Conclusion: A New Era of Bread Making Begins

The unveiling of this Automated Bread Production Line is more than a tech launch—it’s a cultural milestone. Andrew Mafu Machinery is empowering bakers, delighting consumers, and paving the way for a tastier, smarter future.

**Q: What is the bread forming production line by Andrew Mafu?

**A: It’s an automated system that handles all aspects of bread making—from dough preparation to slicing and packaging.

**Q: Is this system suitable for small bakeries?

**A: Yes, its modular design makes it adaptable to both small-scale and large-scale operations.

**Q: How does it maintain bread quality despite being automated?

**A: The system mimics artisanal techniques and offers customizable settings to ensure flavor and texture are preserved.

**Q: What kind of training does Andrew Mafu Machinery provide?

**A: They offer comprehensive in-person and virtual training, along with 24/7 support.

**Q: Where can I buy the automated bread production line?

**A: Visit Andrew Mafu Machinery’s official website or contact their regional partners for orders and demos.

Previous News

Baking Made Easy: Andrew Mafu Machinery’s...Next News

Andrew Mafu Machinery Invites You to the 27th B...

By ADMF

Croissant Production Line: High Efficiency an...

The automatic bread production line is a full...

Efficient Automatic Bread Production Lines fo...