Andrew Mafu Machinery Unveils Advanced Automated Sandwich Production Line, Targeting Global Food Manufacturers

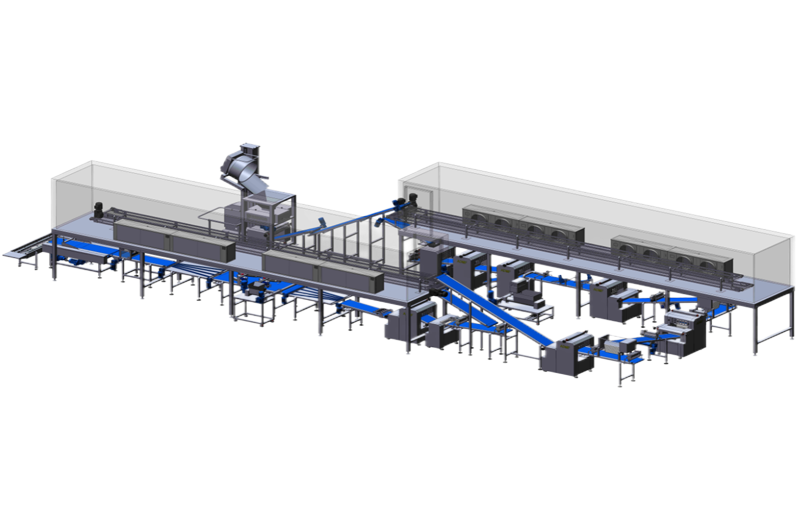

In a significant move poised to reshape efficiency and consistency standards in the prepared foods sector, Andrew Mafu Machinery, a leading innovator in food processing equipment, has officially launched its comprehensive, fully automated Sandwich Production Line. This integrated solution addresses the core challenges of high-volume sandwich manufacturing by combining four specialized, seamlessly integrated machines: the Toast Peeling Machine, Continuous Bread Slicing Machine, Bread Filling Machine, and Ultrasonic Cutting Machine. The line promises substantial gains in output, precision, hygiene, and labor cost reduction for producers worldwide.

The global sandwich market, encompassing retail, foodservice, and institutional segments, continues its robust growth trajectory. However, manufacturers face persistent pressures: rising labor costs, stringent food safety regulations, demand for consistent quality, and the need for faster throughput to meet volume requirements. Andrew Mafu’s new line is engineered specifically to overcome these hurdles, offering a turnkey solution for producing a wide variety of filled sandwiches at scale.

“The modern sandwich producer requires more than just speed; they need reliability, precision filling, clean cuts, and impeccable hygiene integrated into one cohesive system,” stated Mr. Alex Chen, Head of Sales & Marketing at Andrew Mafu Machinery. “Our new production line eliminates traditional bottlenecks, minimizes manual handling, and delivers a consistently perfect product, slice after slice. This isn’t just automation; it’s intelligent sandwich engineering.”

Deconstructing the Line: Core Components & Functions

1. Toast Peeling Machine:

Function: This critical first stage addresses a common issue in automated sandwich lines: efficiently separating toasted or pre-sliced bread slices that tend to stick together after packaging or during handling. The machine gently and reliably peels individual slices from a stack, orienting them correctly for the next stage. It employs specialized mechanisms (often utilizing suction cups, gentle air jets, or precise mechanical fingers) designed to handle delicate toast without tearing or deformation.

Impact: Ensures a smooth, uninterrupted feed into the slicing machine, preventing jams and downtime caused by stuck slices. Crucial for maintaining line speed and eliminating the need for manual separation, a significant labor-intensive step.

2. Continuous Bread Slicing Machine:

Function:Positioned after peeling, this high-speed machine takes the individually separated slices and precisely cuts them to the exact thickness required for the sandwich type (e.g., thin for tea sandwiches, standard for lunch sandwiches). It operates continuously, synchronizing perfectly with the peeling infeed and the filling station outfeed. Features include ultra-sharp, food-grade stainless steel blades, adjustable thickness settings, and often automatic blade sharpening or lubrication systems for consistent performance.

Impact: Delivers uniform bread slices essential for consistent sandwich weight, appearance, and automated handling downstream. Replaces slower, less precise manual or semi-automatic slicers, dramatically increasing throughput and slice consistency.

3. Bread Filling Machine:

Function: The heart of the sandwich assembly. This sophisticated machine precisely deposits measured amounts of filling (spreads like butter/mayonnaise, sliced meats, cheeses, vegetables, salads, or combinations) onto the bottom bread slice as it passes through the station. Depending on the model and configuration, it can handle multiple fillings simultaneously or sequentially, with various depositing technologies (piston pumps for spreads, volumetric cups for chunks, precise layering for slices). Sophisticated models offer recipe management for different sandwich types.

Impact:Achieves accurate portion control, critical for cost management and meeting product specifications. Ensures consistent filling placement and distribution, enhancing product quality and appearance. Significantly reduces labor costs associated with manual filling and minimizes filling waste. Maintains hygiene by enclosing the filling process.

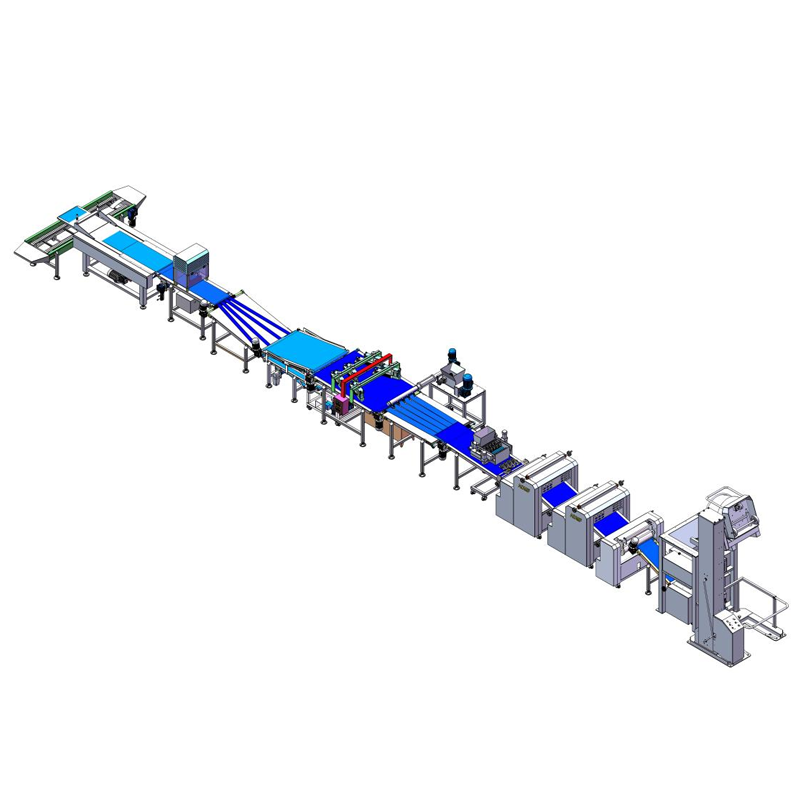

4. Ultrasonic Cutting Machine:

Function: This represents the cutting-edge (literally) of the line. Instead of traditional blades, this machine uses high-frequency ultrasonic vibrations to generate heat at the molecular level along the cutting path. It cleanly and precisely cuts the filled sandwich into halves, quarters, triangles, or other shapes based on programmed settings.

Impact:

Clean Cuts: Virtually eliminates crumbs, smearing, and filling displacement (“squeeze-out”) common with blade cutting, resulting in a pristine, market-ready product.

Sealed Edges:The localized heat generated by the ultrasonic process can slightly melt or seal the edges of certain fillings (like cheese) and the bread, helping to contain moist fillings and potentially extending shelf life slightly.

Hygiene & Maintenance: Non-contact cutting (the horn doesn’t touch the food directly) and lack of blade crevices drastically improve hygiene and simplify cleaning. Ultrasonic systems typically require less maintenance than complex mechanical cutters.

Versatility: Excels at cutting sandwiches with sticky, moist, or multi-layered fillings that would challenge conventional blades.

Integrated System Benefits:

The true power of the Andrew Mafu line lies in the seamless integration of these four specialized machines. Conveyor systems synchronize the movement of product between each stage, ensuring smooth, continuous operation. Programmable Logic Controllers (PLCs) manage the entire process, allowing for easy recipe changes, speed adjustments, and monitoring of key parameters. The line is constructed with food-grade stainless steel throughout, emphasizing durability, corrosion resistance, and ease of sanitation to meet global food safety standards (HACCP, ISO 22000).

Ultrasonic cutting machine

Key advantages for manufacturers include:

Dramatically Increased Output: Capable of producing hundreds, even thousands, of sandwiches per hour, far exceeding manual or semi-automated methods.

Enhanced Consistency & Quality: Uniform slice thickness, precise filling weights, consistent placement, and clean ultrasonic cuts guarantee every sandwich meets specifications.

Significant Labor Reduction:Automates the most labor-intensive steps (peeling, slicing, filling application, cutting), freeing staff for higher-value tasks and reducing reliance on large workforces.

Improved Hygiene & Food Safety: Minimized human contact, enclosed filling processes, easy-clean design, and ultrasonic cutting all contribute to a safer production environment.

Reduced Waste:Precise portion control of fillings and clean cutting minimize product giveaway and spillage.

Scalability:The modular design allows for future expansion or integration with upstream/downstream processes (baking, cooling, packaging).

Market Positioning & Availability:

The Andrew Mafu Sandwich Production Line is targeted at medium to large-scale food manufacturers supplying supermarkets, convenience stores, airline catering, school meal programs, and foodservice distributors. The company emphasizes its capability for customization to handle various bread types (white, whole wheat, brioche, rolls), fillings (from delicate salads to sliced meats), and final product shapes and sizes.

This launch positions Andrew Mafu Machinery firmly within the growing trend of complete automation solutions for the prepared foods industry. As labor shortages persist and quality demands increase, integrated lines like this offer a compelling return on investment through efficiency gains and enhanced product integrity.

For Sales Inquiries & Detailed Specifications:

Companies interested in learning more about the Andrew Mafu Sandwich Production Line, requesting quotes, or scheduling demonstrations are encouraged to contact the Andrew Mafu sales team:

Phone / WeChat / WhatsApp: +86 184 0598 6446

Email: [email protected]

Website:https://www.andrewmafugroup.com/

About Andrew Mafu Machinery:

Andrew Mafu Machinery is a renowned manufacturer and exporter of high-quality food processing machinery based in China. With years of industry experience, the company specializes in designing and producing reliable, efficient, and innovative equipment for various food sectors, including bakery, meat processing, snack food, and ready-to-eat meals. Their commitment to quality, customer service, and technological advancement has established them as a trusted partner for food manufacturers globally.

Previous News

Andrew Mafu Machinery Impresses International C...Next News

Andrew Mafu Machinery Showcases Advanced Baking...

By ADMF

Croissant Production Line: High Efficiency an...

The automatic bread production line is a full...

Efficient Automatic Bread Production Lines fo...