Contents

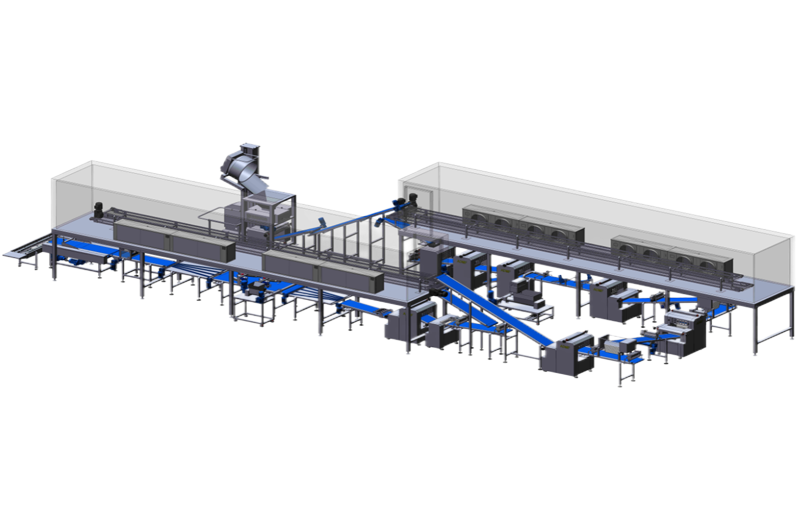

In the ever-evolving world of food technology, few innovations have made as significant an impact as the Automated Bread Line developed by Andrew Mafu Machinery. Known for blending engineering precision with baking passion, the company has once again raised the bar in industrial baking by launching a production line that delivers unmatched efficiency, consistency, and quality.

Gone are the days of tedious manual labor, unpredictable baking times, and inconsistent loaves. The Automated Bread Line from Andrew Mafu Machinery is transforming how commercial bakeries operate. This cutting-edge system allows bakeries to streamline their production process, reduce waste, and dramatically increase output—all while maintaining the handcrafted feel that customers love.

The expertise behind the Automated Bread Line is evident in every stage of its design. With a deep understanding of both mechanical engineering and bakery operations, Andrew Mafu Machinery developed a system that does more than just bake—it thinks, adapts, and delivers.

At the core of this innovation lies a modular architecture, allowing bakeries to customize their line according to their unique needs. Whether producing sandwich bread, artisan loaves, or high-volume retail products, the system’s intelligent configuration ensures optimal performance across the board.

What sets this machine apart? Let’s break it down:

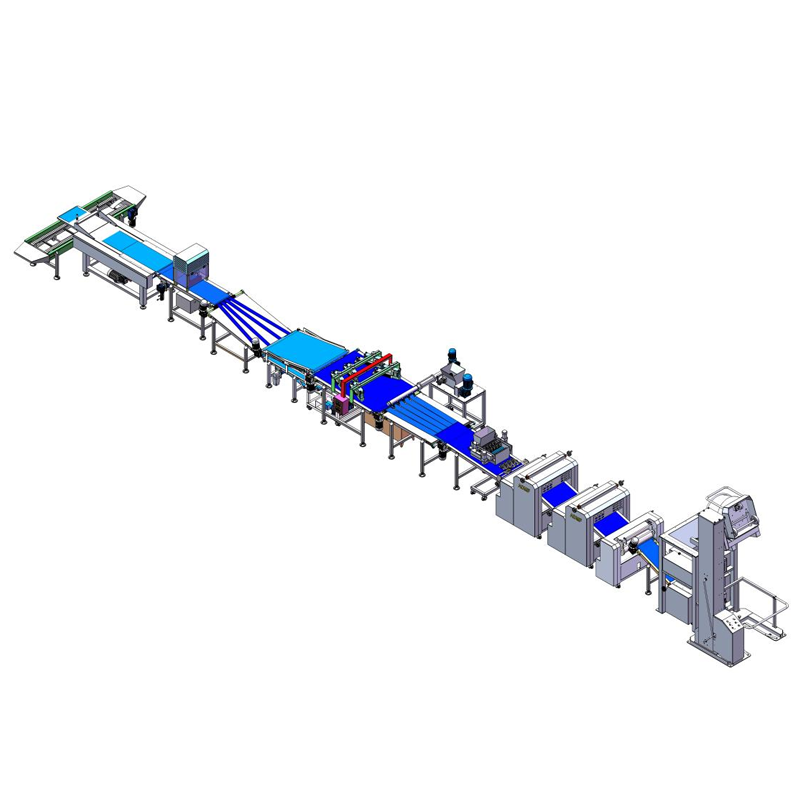

Dough Lifting Machine-After the Dough Rising Machine can be automatically unloaded, and then after two hexagonal stick shaping, so that the dough can be neat and smooth into the first freezer, greatly reducing the physical strength of the workers.

Rolling and Pressing Machine-A single rolling machine and pressing machine are combined into one, eliminating air bubbles and realizing the perfect combination of dough and ghee immediately after rolling out the dough. The dough comes out flat, even and bubble-free after the 2-in-1 rolling machine, which guarantees the shape and texture of the molded bread.

Freezer-Using double-sided 304 insulation board, the temperature of freezing tunnel or frozen noodles can be adjusted to -15°~25°, effectively controlling the temperature of the dough with yeast, the freezer mainly plays a role in the relaxation of the dough and the control of the rise of yeast.

Cutting Table-Improved frequency conversion plus encoder. Belt, cutter are imported servo control, to achieve cutting speed, high precision, neat cut. Cutting table can be arbitrarily adjusted length of various products, suitable for the production of a variety of products.

Arranging Tray Machine-The introduction of Germany’s advanced pull-out arranging method, chain plate arranging high precision, according to the differentiation of different products as the adjustment, instead of manual arranging greatly reduce labor. Overcome the vertical plate machine of one side of the plate and covers an area of large problems, a full set of microcomputer control technology, whether in the speed or in the accuracy of higher than the vertical plate machine, man-machine screen is simple and simple, conducive to the modification of the factory technicians and maintenance, the chain plate type to do to docking automated production line in and out of the disk, the complete realization of the whole process of automation of the disk into the disk out of the disk purpose.

This isn’t just automation—it’s intelligent baking at its best.

Andrew Mafu Machinery isn’t new to the game. With years of industry experience and a proven track record, their name is synonymous with reliability and innovation. What distinguishes them from others is their ability to anticipate market needs and build future-ready solutions.

The team behind the bread machine line consists of food technologists, mechanical engineers, and experienced bakers. This interdisciplinary approach ensures that each product launched meets both the functional and emotional needs of its users.

One of the biggest challenges in commercial baking is increasing output without compromising quality. Andrew Mafu’s Automated Bread Line tackles this issue head-on. It offers an incredible throughput capacity—up to 10,000 loaves per hour—without sacrificing taste, texture, or crust quality.

Bakeries that have adopted the line report not just faster production, but a noticeable boost in product consistency, shelf life, and customer satisfaction.

From Europe to Africa, and Asia to the Americas, the Andrew Mafu brand has become a global symbol of baking innovation. Major bakery chains in South Africa, the Philippines, and Indonesia have adopted the Automated Bread Line with remarkable success.

In one Southeast Asia bakery, switching to the ADMF system resulted in:

35% reduction in production costs

50% increase in daily output

Drastic reduction in product returns due to consistency and quality

These aren’t just numbers—they represent real economic growth and better experiences for bakery owners and consumers alike.

What makes Andrew Mafu Machinery stand out isn’t just the tech—it’s the people. When bakeries invest in their bread line, they receive more than just machinery. Each client gains access to:

On-site installation and training

24/7 multilingual customer support

Maintenance contracts with real-time diagnostics

Regular software updates to enhance performance

This end-to-end support model ensures smooth operation from Day 1.

Modern consumers care about sustainability, and so does Andrew Mafu Machinery. The Automated Bread Line is designed with eco-friendly features:

Energy-efficient motors and ovens

Low-noise operation

Reduced carbon footprint

Bakeries using this system not only increase profits but also reduce their environmental impact—an important factor in today’s marketplace.

Looking ahead, the company is already integrating AI and IoT capabilities into their next-gen models. Imagine a bread line that can:

Predict consumer demand using historical data

Auto-adjust recipes based on flour batch quality

Monitor supply chain disruptions and re-route production plans

With these advancements, the bakery of tomorrow will not only be smart but self-optimizing.

“We’ve been in business for 40 years and never thought we’d see this kind of leap. The Mafu bread line is a game-changer.”

– Theresa DuPlessis, Owner, Durban Bakehouse

“What used to take us 16 hours, we now do in 5—with better results!”

– Luis Hernandez, Plant Manager, Pan Rico Foods, Mexico

In a world where speed and quality often clash, Andrew Mafu Machinery proves you can have both. Their Automated Bread Line is more than just a machine—it’s a vision of the future of baking.

Whether you’re a small artisan bakery or a global production facility, investing in Andrew Mafu’s bread machine line is a step toward smarter, more efficient, and more profitable operations.

Conclusion: The Future of Baking Has Arrived

Baking isn’t just about flour and yeast—it’s about passion, precision, and progress. With the launch of its Automated Bread Line, Andrew Mafu Machinery has baked innovation right into the heart of the industry.

The message is clear: If you want to stay ahead in today’s fast-paced food industry, you need a partner like Andrew Mafu Machinery. Their technology doesn’t just support your bakery—it transforms it.

Q1: What is an Automated Bread Line?

A: It’s a fully integrated system that automates all steps in bread production—from mixing and proofing to baking and packaging.

Q2: Who is Andrew Mafu Machinery?

A: A leading innovator in bakery machinery, known for creating efficient and intelligent bread production systems.

Q3: Can small bakeries use this system?

A: Yes! The line is modular and scalable, making it perfect for bakeries of any size.

Q4: How does the bread line improve product quality?

A: Through smart sensors and real-time monitoring that ensure optimal baking conditions and consistency.

Q5: Is training provided?

A: Absolutely. Andrew Mafu Machinery provides comprehensive training and ongoing support to all clients.

Previous News

ADMF Tech-Driven Bread Forming Production Line ...Next News

Andrew Mafu Machinery Debuts Innovative Automat...

By ADMF

Croissant Production Line: High Efficiency an...

The automatic bread production line is a full...

Efficient Automatic Bread Production Lines fo...