Contents

- 1

- 2

- 3 Product Overview: Automatic Trays Arrangement Machine

- 4

- 5 Technical Parameters

- 6 Factory Visit and Machine Testing

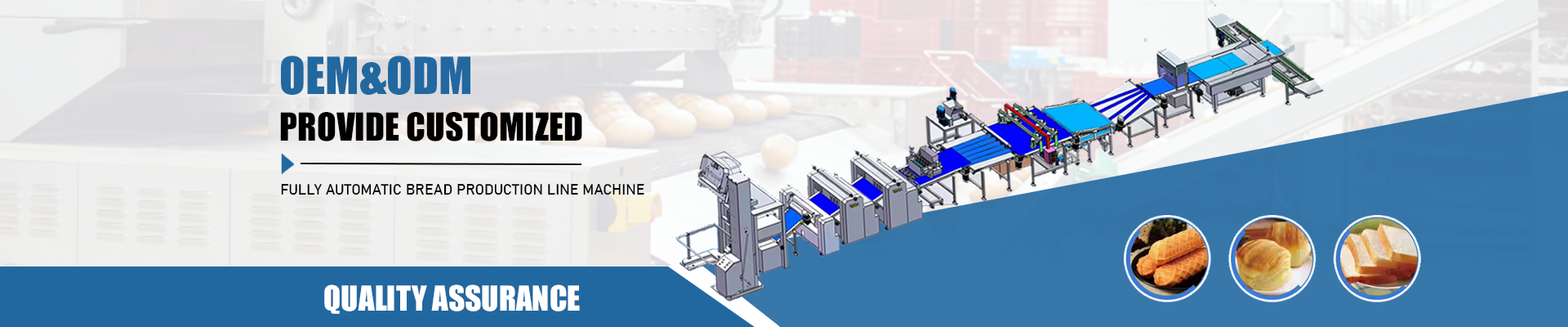

- 7 Visit to a Bakery Using Andrew Mafu’s Automated Bread Production Line

- 8 Professional Insights from Andrew Mafu Engineers

- 9

- 10 Client Feedback and Future Cooperation

- 11 Professional FAQ (Machine-Focused)

From December 6th to 8th, Andrew Mafu Machinery welcomed a Canadian client for an in-depth inspection of the newly developed Automatic Trays Arrangement Machine. The visit included comprehensive machine testing, factory tours, technical discussions, and an on-site demonstration at a bakery using an automated bread production line supplied by Andrew Mafu. The client provided highly positive feedback regarding equipment quality, operational stability, and engineering precision.

This visit marks another milestone in Andrew Mafu Machinery’s expanding global presence, reinforcing its commitment to high-efficiency bakery automation solutions.

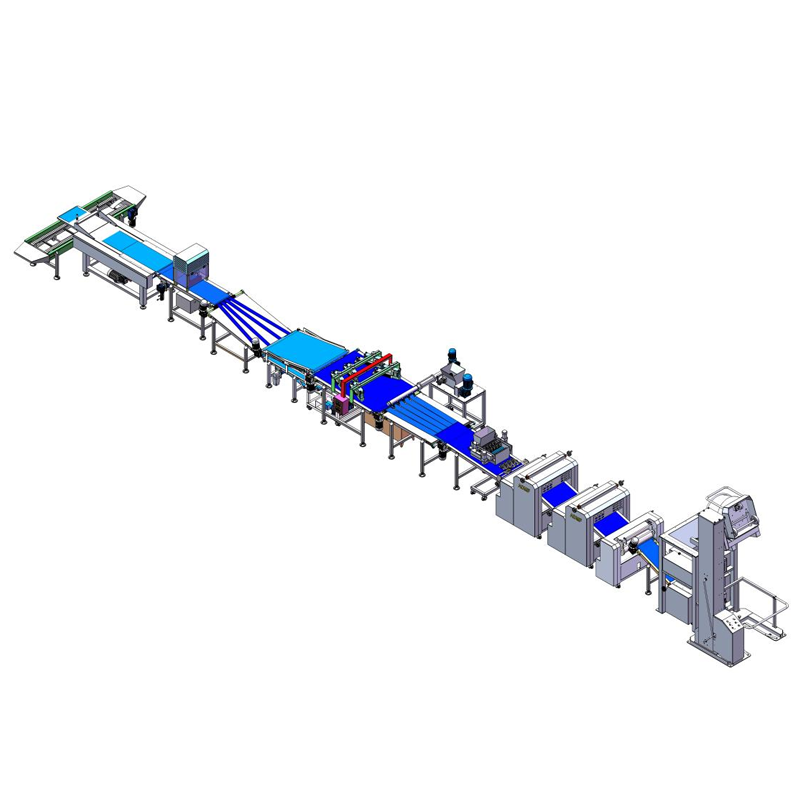

Product Overview: Automatic Trays Arrangement Machine

As part of the inspection, the client reviewed the full structure, performance, and technical specifications of the latest Automatic Trays Arrangement Machine, a fully automated system designed for high-volume bakery operations.

1. Function and Application

This automated equipment is designed for industrial food processing and tray-handling environments.

Engineered with the McgsPro industrial-grade HMI control system, the machine delivers precise tray arrangement, synchronized conveyor positioning, and efficient material distribution for:

-

dough pieces

-

pastry blanks

-

pre-shaped bakery items

-

laminated dough products

It supports both manual and automatic modes, making it suitable for diverse bakery configurations—from traditional production rooms to fully automated industrial factories.

The system significantly improves production efficiency, reduces manual labor, and enhances product consistency in mass-production environments.

Technical Parameters

Below is the complete specification list presented to the Canadian client during inspection:

| Parameter | Specification |

|---|---|

| Conveyor Belt Speed | 0.5–2.0 m/min (adjustable) |

| Chain Positioning Accuracy | ±1 mm |

| Power Supply Requirements | AC 380V / 50Hz |

| Equipment Power | 7.5 kW |

All technical indicators were validated during repeated testing cycles, demonstrating stable and accurate operation under both low- and high-speed settings.

Factory Visit and Machine Testing

During the three-day factory visit, the Canadian client conducted multiple tests focusing on:

-

tray alignment consistency

-

conveyor chain positioning precision

-

sensor response time

-

PLC logic and operation interface

-

stability during continuous high-speed running

-

noise control and vibration resistance

-

stainless-steel hygiene design

Engineers at Andrew Mafu adjusted the system in real-time based on operational simulations to ensure performance matched the client’s production requirements.

The client highlighted the machine’s smooth tray transition, precise positioning, and intelligent interface as key strengths of Andrew Mafu’s engineering capabilities.

Visit to a Bakery Using Andrew Mafu’s Automated Bread Production Line

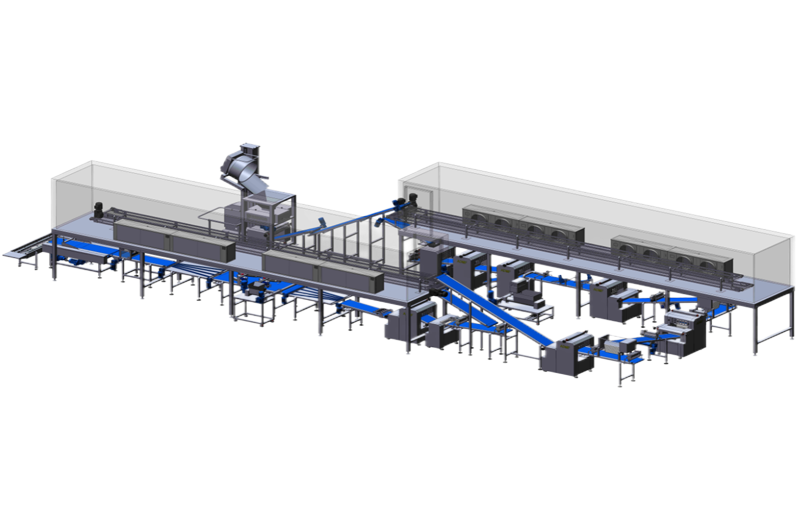

To provide real-world insights into industrial automation, the Andrew Mafu team accompanied the client to a local bakery using the company’s fully automated bread production line.

The on-site system demonstrated:

-

dough dividing and rounding

-

continuous proofing

-

moulding and shaping

-

automatic tray feeding

-

large-scale baking

-

cooling and slicing automation

The client observed how tray-handling modules—such as the Automatic Trays Arrangement Machine—integrate seamlessly with upstream and downstream processes in a complete automated system.

The bakery operators shared their experience regarding:

-

improved production capacity

-

reduced labor requirements

-

consistent bread quality

-

stable long-term machine performance

This practical demonstration significantly strengthened the client’s confidence in implementing automation in their own facility.

Professional Insights from Andrew Mafu Engineers

During technical discussions, Andrew Mafu engineers shared expert perspectives on tray-handling automation:

“Tray alignment accuracy directly affects moulding and downstream performance.”

Even a 1–2 mm deviation may cause issues in high-speed bread and pastry lines.

“McgsPro-based HMI improves real-time monitoring and recipe switching.”

This ensures fast product changeovers during multi-SKU bakery production.

“Chain positioning accuracy of ±1 mm ensures compatibility with international tray standards.”

This is essential for export bakeries and standardized mass production.

“The 7.5 kW system supports long-hour continuous running without overheating.”

The machine is engineered for heavy-duty industrial loads.

“Modular design allows integration with forming lines, bread lines, and cold-dough lines.”

Ensuring high flexibility for future expansion.

These insights provided the client with a clearer understanding of the technical advantages and future potential of the machine.

Client Feedback and Future Cooperation

By the end of the visit, the Canadian client expressed strong satisfaction with:

-

machine build quality

-

tray alignment precision

-

user-friendly interface

-

automation synchronization capability

-

manufacturing transparency

-

Andrew Mafu Machinery’s engineering professionalism

The client confirmed their intention to continue expanding cooperation in areas such as:

-

automated bread production

-

dough forming modules

-

advanced pastry handling systems

-

factory-wide automation upgrades

Andrew Mafu Machinery looks forward to supporting the client’s long-term production strategy.

Professional FAQ (Machine-Focused)

1. What materials can the Automatic Trays Arrangement Machine handle?

It is suitable for dough pieces, pastry blanks, laminated dough, frozen dough, and semi-finished bakery items.

2. Can the machine integrate with upstream dough processing equipment?

Yes. It can connect with dough dividers, rounders, moulders, and sheeters through synchronized PLC communication.

3. How accurate is the tray positioning system?

The chain positioning accuracy is ±1 mm, ensuring precise alignment for automated loading modules.

4. What HMI system does the machine use?

It uses the McgsPro industrial-grade HMI for stable operation, recipe management, and system diagnostics.

5. Is the machine suitable for continuous high-speed production?

Yes. With a 7.5 kW power system and industrial conveyor design, it supports long-hour, high-speed operation.

6. Can tray sizes be customized?

The machine supports adjustable tray width/length configurations and can be modified according to customer standards.

7. How difficult is daily maintenance?

The system is designed with accessible covers, washable surfaces, and modular components for easy maintenance.