Andrew Ma Fu supplies turnkey automatic bread production line solutions—improve efficiency, consistency and food safety with China’s experienced bakery equipment maker.

Contents

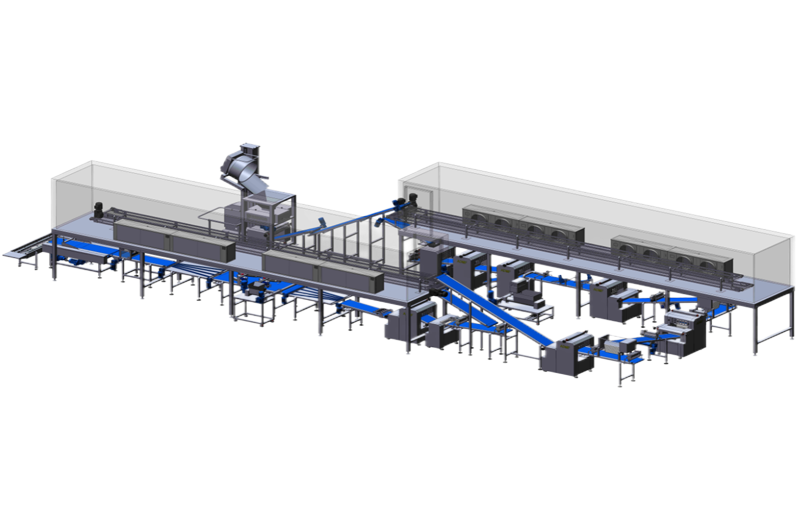

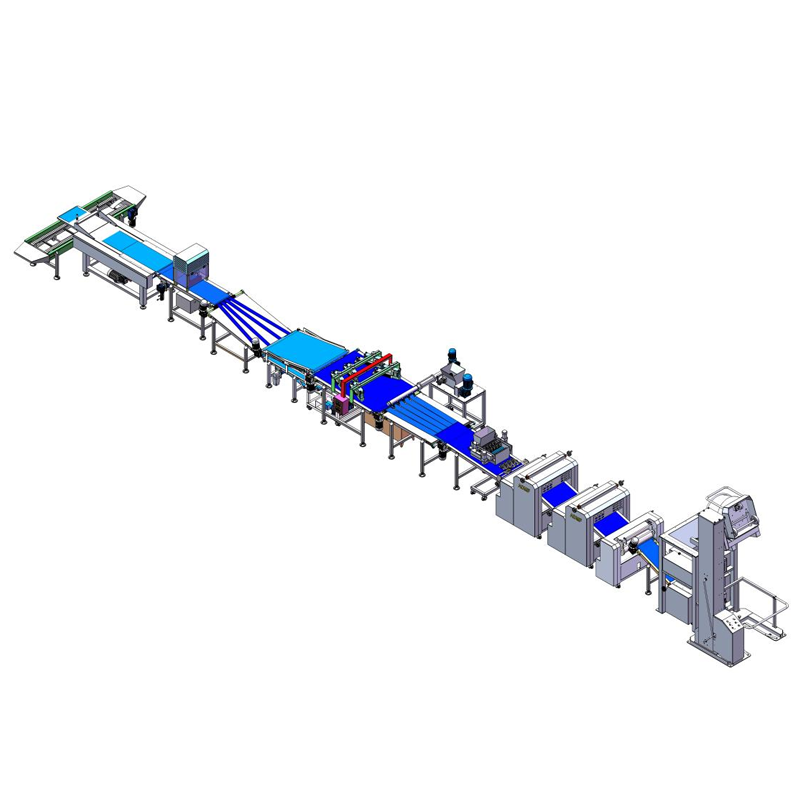

As a leading Chinese manufacturer of bakery automation systems, Andrew Ma Fu Machinery provided a full-scale bread production line for a commercial bakery in Malaysia. This project demonstrates how advanced automation technology can boost productivity, reduce costs, and maintain consistent bread quality across large-scale production.

(Key claims in this case study are supported by industry research and technical literature; see References at the end.)

Client: Malaysia Industrial Bakery Factory

Production Line: Fully automatic bread production system

Capacity: 3,000 pcs/hour

Delivered by: Zhangzhou Andrew Ma Fu Machinery Co., Ltd.

The client’s main challenges were:

Inconsistent product quality due to manual processes

High labor dependency

Limited production capacity

Difficulty maintaining hygiene standards

Our engineering team designed a complete bread production line to achieve fully automated, hygienic, and energy-efficient operations.

The provided production line included:

High-speed horizontal dough mixer – ensures uniform texture

Automatic dough divider and rounder – for accurate weight control

Fermentation & proofing system – precise temperature and humidity control

Tunnel oven – stable baking quality with energy-efficient design

Cooling conveyor – for optimal moisture balance

Bread slicing and packaging system – reduces manual handling

All modules are connected via a central PLC system allowing automatic synchronization and real-time monitoring. PLC-based control and modular batch control are proven to deliver more consistent output and easier energy management.

| KPI | Before | After |

|---|---|---|

| Production Efficiency | 1,000 pcs/hour | 3,000 pcs/hour |

| Labor Requirement | 12 workers | 4 workers |

| Waste Reduction | 10% | 2% |

| Product Consistency | Medium | High uniformity |

| Energy Efficiency | Standard | +25% Improvement |

Key Outcomes:

Reduced total operation cost by 35%

Increased product consistency and hygiene compliance

Simplified maintenance and operator training

Energy-saving measures such as optimized tunnel oven design and waste-heat recovery can materially reduce fuel consumption and CO₂ emissions in industrial baking operations — several engineering studies and applied projects report measurable savings when heat recovery or optimized air preheating is implemented.

Expert Panel: Andrew Ma Fu R&D Department

Why is automation critical in modern bread production?

Automation addresses persistent labor shortages and rising labor costs while improving product consistency and safety — trends well documented across global bakery markets.

How does PLC integration improve operational reliability?

PLCs allow real-time monitoring and closed-loop control of temperature, proofing time, conveyor speed and ovens — reducing overbaking/undercooking and increasing yield. Modular PLC/batch control systems are widely recommended in industry guides.

What materials are recommended for food-grade production lines?

For food-contact surfaces we recommend 304 or 316 stainless steel depending on environment (316 if exposure to salts/acidic media is expected). Both are considered food-grade and commonly used in hygienic equipment design.

How do automatic bread lines help sustainability?

Combining energy-efficient ovens with heat-recovery systems and optimized process control reduces energy consumption; research shows viable waste-heat recovery strategies for bakery ovens and measurable fuel savings.

Which technologies will shape bakery automation in the near future?

AI-driven quality control, machine-learning–based process optimization, and remote/predictive maintenance are accelerating adoption — industry surveys and recent projects indicate growing AI deployment across bakery factories.

“With Andrew Ma Fu’s automatic bread production line, our factory achieved triple output with fewer workers. The system runs smoothly and maintenance is simple. We’re now expanding to a second line next year.”

— Production Director, Malaysia Bread Factory

Q: What is the lead time for a complete bread production line?

A: Typical delivery lead time is 12–18 weeks after final design approval for standard configurations; fully customized plants may require 18–26 weeks.

Q: Can the line be customized for different loaf sizes and recipes?

A: Yes. The divider/rounder, depositor heads and conveyor speeds are adjustable. We provide custom tooling and PLC recipes to handle different loaf weights and dough hydration levels.

Q: What kinds of warranties and after-sales service do you offer?

A: Standard warranty is 12 months from commissioning. After-sales support includes remote diagnostics, spare parts supply, and optional on-site maintenance contracts.

Q: How do you handle installation and commissioning overseas?

A: We provide full installation support — remote guidance plus on-site engineers as required. We can manage logistics, local compliance checks, and operator training.

Q: What are the energy-saving features of your tunnel ovens?

A: Options include zoned heating control, insulated kiln design, optimized combustion or electric elements, and waste-heat recovery integration for preheating proofing air or generating process steam.

Q: Are your machines CE / food-safety compliant?

A: Yes — machines can be supplied with CE conformity documentation and built using food-grade materials and hygienic design principles.

Q: How do you ensure product quality and reduce rejects?

A: Through closed-loop PLC controls, precise weighing/dividing, consistent proofing environment, and optional vision-based quality checks (AI modules) to detect irregular products prior to packaging.

15+ years’ experience in bakery automation and production-line engineering

Custom design solutions for different loaf types and factory layouts

Global service network for installation and after-sales support

CE and food-safety compliant machinery built with 304/316 stainless steel in food-contact areas

Proven track record with clients in 120+ countries

Bakery robots: How automation is solving bakery production challenges, HowToRobot.

Chowdhury JI et al., Waste heat recovery integration options for commercial bakery ovens (ScienceDirect).

Automating Industrial Bakery Production Lines, Naegele Inc. technical guide (PDF).

Food Grade Stainless Steel: 304 vs 316, AZoM.

AI, ML & Data: Automation Revolutionizing Bakery & Snacks, BakeryAndSnacks.

Previous News

Andrew Mafu Machinery Launches Fully Automatic ...Next News

Mexican Clients Visit ADMF Factory: Exploring t...

By ADMF

Croissant Production Line: High Efficiency an...

The automatic bread production line is a full...

Efficient Automatic Bread Production Lines fo...