Contents

In today’s competitive baking industry, continually enhancing production efficiency and product quality is essential. Optimizing your bakery production line not only increases output but also ensures consistency and excellence in your products.

A bakery production system encompasses the entire process of transforming raw materials—such as wheat flour, sugar, yeast, butter, water, and salt—into finished baked goods. This process includes mixing, fermentation, shaping, baking, and packaging. Depending on the scale and automation level, bakery production can be categorized into:

Artisanal Production: Relying primarily on manual labor with minimal specialized machinery, suitable for small-scale operations.

Semi-Automated Production: Combining manual labor with semi-automatic machines, ideal for medium-sized enterprises.

Fully Automated Production: Highly dependent on automated equipment, suitable for large-scale operations, enabling efficient and standardized production processes.

Andrew Ma Fu food baking machinery products have spread all over the world

Implementing mechanization in the production process offers several competitive advantages:

Increased Production Efficiency: Automated equipment can operate continuously, significantly boosting production speed and reducing manual intervention.

Product Standardization: Mechanized production ensures uniformity in product weight, shape, and quality, meeting market demands for standardized products.

Precise Production Control: Automated systems can accurately control various production parameters, such as temperature, humidity, and time, ensuring consistent product quality.

Achieving an efficient production process requires optimization in the following areas:

Physical Facilities: Design production facilities to meet health and safety standards, ensuring a smooth production flow.

Operational Processes: Implement best manufacturing practices, including strict hygiene controls, preventive maintenance programs, temperature and humidity controls, and quality control systems for raw materials.

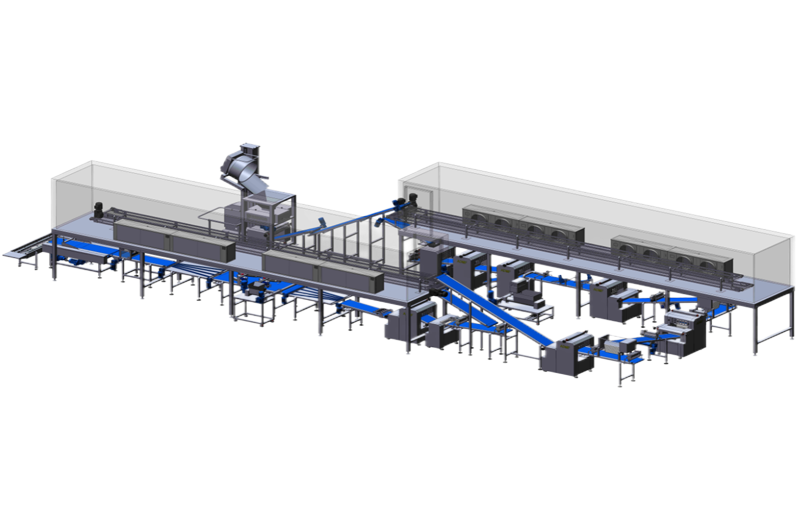

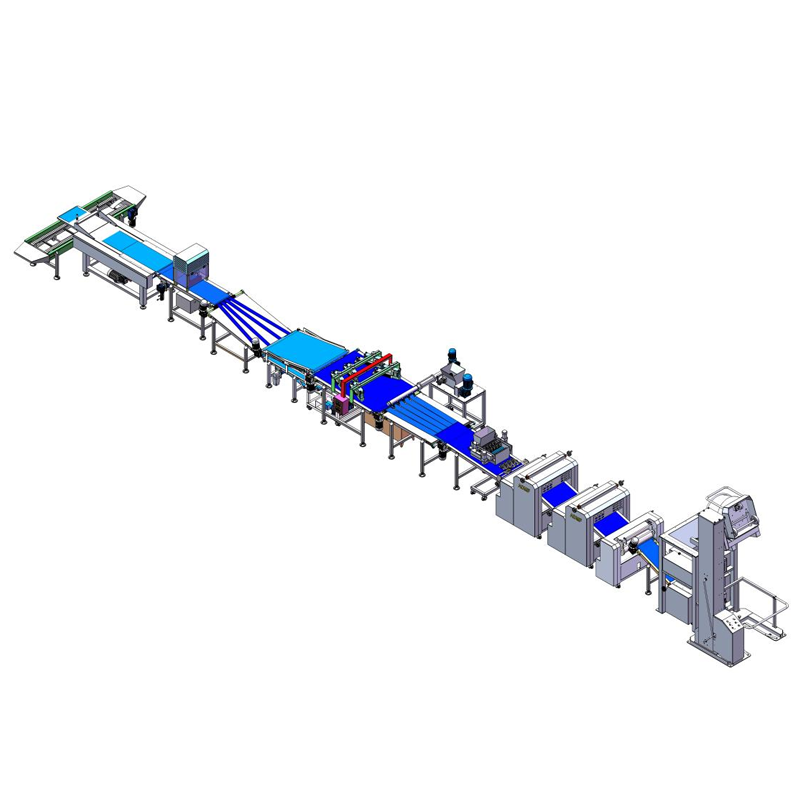

At Andrew Ma Fu Machinery, we are dedicated to providing efficient production line solutions. Our equipment is modular, allowing you to offer a diverse range of products on the same line. Additionally, our equipment enhances production capacity, ensures consistent product quality, and retains the essence of handcrafted production. Our complete production lines include:

Each of our machines is designed to make the production process as efficient as possible while maintaining high-quality operations. Moreover, they can process folded, cut, or rolled pastry products on the same line.

Regardless of your bakery’s size, optimizing your production line will bring benefits that allow you to grow, be competitive, productive, sustainable, and therefore successful. We are committed to helping you increase efficiency and yield in the production of bakery and pastry products. Our team of experts will be happy to discuss options for scaling up your bakery production. Contact us, and we will help you create a design for partially or fully automated production, boosting your production precisely and in line with your investment possibilities.

By ADMF

Croissant Production Line: High Efficiency an...

The automatic bread production line is a full...

Efficient Automatic Bread Production Lines fo...