Contents

Opening a Bakery Equipment is a business venture full of opportunities. The raw material costs of bread and related products are relatively low, but through careful production and sales, there is a considerable profit margin. However, to ensure product quality and production efficiency, it is crucial to select the right bakery equipment.

Mixers are one of the core equipment in a bakery, used to mix ingredients such as flour, water, and yeast into a uniform dough. Good mixing helps to activate the gluten and yeast, ensuring the softness and taste of the bread. Common types of mixers include:

Ovens are one of the core pieces of bakery equipment, and choosing a suitable oven is crucial for the baking effect. Common types of ovens include:

The proofer is used to provide an ideal temperature and humidity environment to promote the fermentation process of the dough and enhance the softness of the bread. Select a proofer with temperature and humidity control functions to ensure the fermentation effect.

Refrigeration equipment is used to store perishable ingredients such as butter, cream, and fresh milk, ensuring the freshness and safety of the ingredients. In addition, refrigerating the dough can extend its shelf life, making it convenient for the store to carry out batch production.

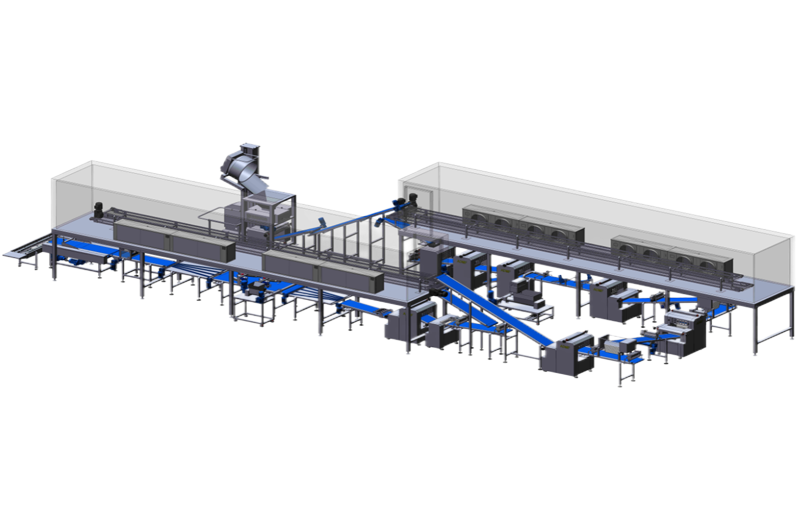

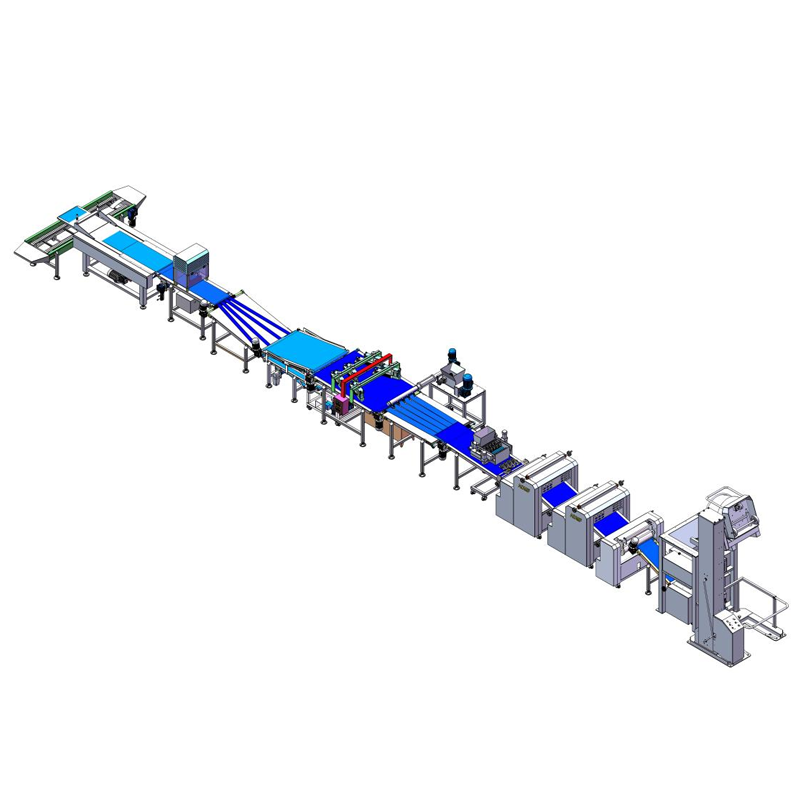

Packaging equipment is used to automatically package the baked bread to ensure the hygiene and aesthetics of the products. Select suitable packaging materials and packaging methods to meet the needs of different bakery products.

For consumers who like sandwiches, a bread slicer is essential equipment. It can cut the bread into even slices, making it convenient for consumers to use.

The display case is used to display and store baked goods such as bread and cakes. It has functions such as constant temperature and humidity retention, which can maintain the taste and freshness of the baked goods. At the same time, the display case can also enhance the customer’s purchasing experience, improving sales and brand image.

The cleaning equipment is used to wash baking utensils and dishes, improving work efficiency. Select cleaning equipment with a high-temperature disinfection function to ensure the cleaning effect, crucial for maintaining high hygiene standards in your bakery.

Storage containers are used to store raw materials and tools, keeping the working area tidy and organized. Select materials that are heat-resistant and easy to clean, such as stainless steel. Proper storage is key to maintaining the quality of raw ingredients.

Auxiliary equipment includes workbenches, storage racks, etc., which are used for the operation and processing of the dough. Select materials that are heat-resistant and easy to clean, such as stainless steel.

When selecting bakery equipment, it is recommended to make a reasonable configuration according to the scale of the store, the types of products, and the budget. High-quality equipment can not only improve production efficiency but also ensure product quality and enhance customer satisfaction.

In addition, regularly maintain and service the baking equipment to ensure its normal operation and extend its service life. When purchasing equipment, it is recommended to choose reputable suppliers to ensure the quality of the equipment and after-sales service.

In conclusion, the reasonable configuration and maintenance of baking equipment are one of the keys to the success of opening a bakery. By carefully selecting and managing the equipment, you can provide high-quality bread and pastries, meet the needs of customers, and enhance the competitiveness of the store.

The company brand “Andrew Ma Fu” provides you with high-quality bakery equipment and comprehensive services to help you achieve success in the bakery business.

Previous News

How and why optimize your bakery production line?Next News

Equipment handling: how to do it safely?

By ADMF

Croissant Production Line: High Efficiency an...

The automatic bread production line is a full...

Efficient Automatic Bread Production Lines fo...