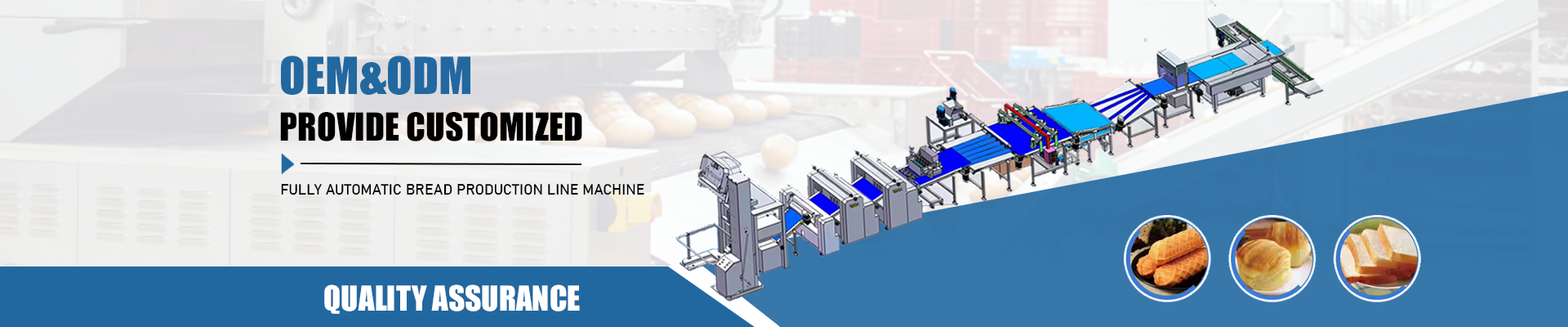

As 2025 comes to a close, Andrew Mafu Machinery reflects on a year defined by technological advancement, global expansion, and a rapidly growing demand for automated bakery production solutions. The global bakery sector continued its shift toward high-efficiency, high-output, and food-safe production systems—creating strong momentum for industrial automation manufacturers worldwide.

This year-end review highlights key market developments, major achievements across Andrew Mafu’s product lines, and strategic milestones that shaped 2025.

Global Market Shifts: A Strong Year for Bakery Automation

The industrial bakery industry saw accelerated growth in 2025, driven by three major forces:

1. Rising worldwide demand for packaged bread and ready-to-eat products

Urbanization and changing consumer lifestyles boosted production requirements for toast, sandwich bread, and bakery snacks.

2. Labor shortages pushing towards full automation

More factories—especially in North America, Southeast Asia, and the Middle East—shifted to automated lines to maintain stable output and reduce labor dependency.

3. Increasing food safety standards

Hygienic design, stainless-steel structures, smart sensors, and automated handling became essential.

With these global trends, industrial lines such as croissant systems, high-hydration toast lines, and fully automated bread lines received expanded investment from bakery manufacturers.

Product Line Growth: Strong Performance Across All Categories

Throughout 2025, Andrew Mafu Machinery observed significant growth across multiple production line categories.

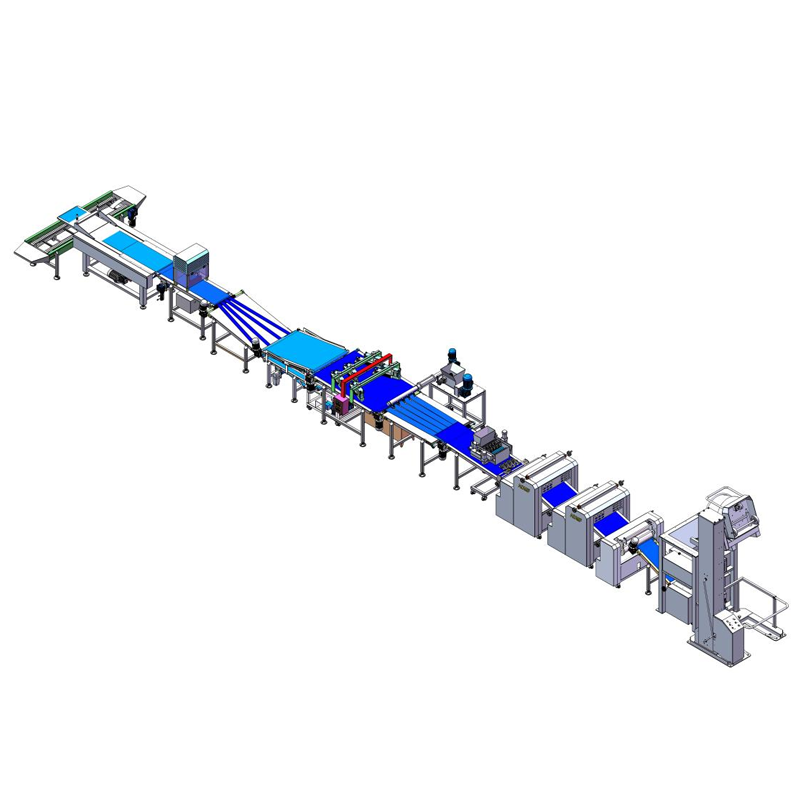

Liy pwodiksyon pen otomatik

Demand increased in emerging markets, especially in factories upgrading from semi-automatic to full automation.

Key improvements included:

-

more stable dough rounding

-

enhanced proofing control

-

accuracy in final forming

-

energy-efficient tunnel alternatives

High-Hydration Toast Bread Line

This became one of the top-requested lines of the year.

Customers favored:

Liy pwodiksyon kwasan

Croissant consumption grew sharply in the Middle East, Southeast Asia, and South America.

The AMF croissant line saw upgrades including:

-

improved sheeting smoothness

-

precise roll forming

-

adjustable lamination layers

-

continuous high-speed operation

Liy pwodiksyon pen sandwich

This category experienced rapid expansion thanks to growing demand for ready-to-eat products.

Modules such as toast peeling, spreading, automated filling, and ultrasonic cutting were widely adopted.

2025 Key Achievements at Andrew Mafu Machinery

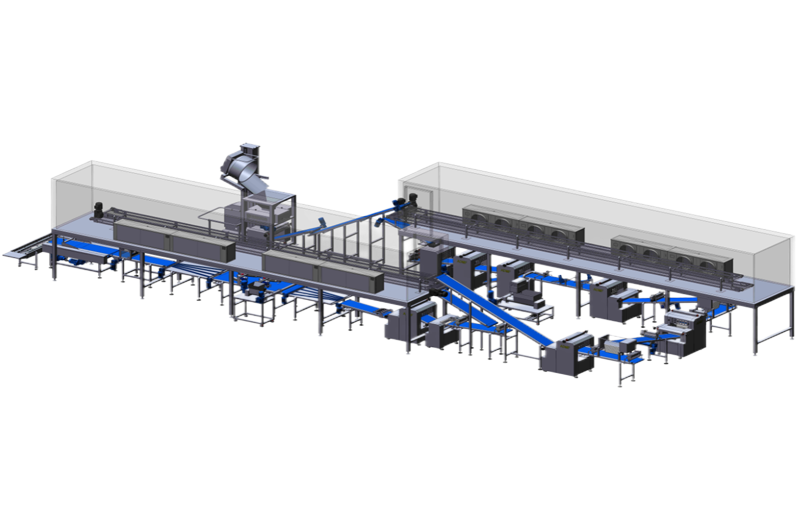

1. Factory Capacity Expansion

To support increasing orders, the company expanded:

-

machining workshops

-

assembly areas

-

QC laboratories

-

component storage areas

The upgraded facility allows more efficient workflow and reduced lead times.

2. Enhancements in R&D and Automation Control

The engineering team delivered multiple innovations:

-

improved PLC synchronization

-

smoother dough-sheeting algorithms

-

higher lamination precision

-

reduced mechanical vibration

-

advanced hygienic design with fewer contamination points

3. Strong Global Installations

Over the year, equipment installations were completed in:

-

Saudi Arabia

-

UAE

-

Indonesia

-

Egypt

-

Chile

-

Vietnam

-

Turkey

-

South Korea

-

Russia

-

and multiple EU markets

These installations ranged from mid-size bakery plants to national-scale industrial factories.

4. Specialized Custom Projects

2025 brought a surge in requests for:

-

custom baguette forming systems

-

local-style bread shaping modules

-

higher-speed slicing designs

-

flexible sandwich customization units

This reflects the market’s shift toward region-specific product innovation.

Leadership Message: A Year of Global Progress

“2025 has shown us the importance of strong partnerships and continuous innovation.

We are grateful for the trust placed in our automated bakery solutions across so many regions.

Entering 2026, we remain committed to delivering more intelligent, efficient, and reliable production technologies to the global bakery industry.”

— Andrew Mafu Machinery Management Team

2025 at a Glance — Key Numbers

-

120+ countries served

-

300+ employees across production, R&D, and service

-

200+ automated lines delivered worldwide

-

8 new technology upgrades across bread, toast, croissant, and sandwich systems

-

20,000 m² of modern manufacturing facilities

These numbers reflect not only the company’s growth, but also the growing global demand for automated bakery equipment.

Looking Ahead to 2026

The company is preparing new technology upgrades focusing on:

-

smart monitoring systems

-

AI-assisted dough handling

-

higher-speed croissant forming

-

improved spreading & ultrasonic cutting

-

energy-saving mechanical design

-

enhanced international service support

The goal is to deliver bakery equipment that is smarter, more stable, and more adaptable to global market needs.

FAQ

1. What were the strongest-selling production lines in 2025?

High-hydration toast lines, croissant lines, sandwich lines, and automatic bread lines.

2. Which markets grew the fastest this year?

Middle East, Southeast Asia, Africa, and Eastern Europe.

3. Did Andrew Mafu upgrade its factory this year?

Yes—machining, assembly, QC, and storage capacity were all expanded.

4. What technical advancements were introduced?

PLC upgrades, improved dough-handling methods, lamination precision, and ultrasonic cutting improvements.

5. What is the focus for 2026?

Smarter automation, digital monitoring, higher efficiency, energy-saving designs, and customized solutions.