2025 yil nihoyasiga yetar ekan, Endryu Mafu Machinery texnologik taraqqiyot, global kengayish va avtomatlashtirilgan non ishlab chiqarish yechimlariga tez ortib borayotgan talab bilan belgilangan yilni aks ettiradi. Global non mahsulotlari sektori yuqori samarali, yuqori mahsuldorlikka ega va oziq-ovqat uchun xavfsiz ishlab chiqarish tizimlariga o'tishni davom ettirdi - bu butun dunyo bo'ylab sanoat avtomatlashtirish ishlab chiqaruvchilari uchun kuchli turtki yaratdi.

Yil yakuni bo'yicha ushbu sharhda bozorning asosiy o'zgarishlari, Endryu Mafuning mahsulot liniyalari bo'yicha katta yutuqlar va 2025 yilni shakllantirgan strategik bosqichlar yoritilgan.

Global bozordagi o'zgarishlar: nonvoyxonalarni avtomatlashtirish uchun kuchli yil

Sanoat non ishlab chiqarish sanoati 2025 yilda uchta asosiy kuch ta'sirida jadal o'sishni kuzatdi:

1. Butun dunyoda qadoqlangan non va tayyor mahsulotlarga talab ortib bormoqda

Urbanizatsiya va iste'molchi turmush tarzining o'zgarishi tushdi, sendvich non va non mahsulotlari uchun ishlab chiqarish talablarini oshirdi.

2. Ishchi kuchi tanqisligi to'liq avtomatlashtirishga intilmoqda

Ko'proq zavodlar, ayniqsa Shimoliy Amerika, Janubi-Sharqiy Osiyo va Yaqin Sharqda barqaror ishlab chiqarishni saqlab qolish va mehnatga bog'liqlikni kamaytirish uchun avtomatlashtirilgan liniyalarga o'tdi.

3. Oziq-ovqat xavfsizligi standartlarini oshirish

Gigienik dizayn, zanglamaydigan po'latdan yasalgan konstruktsiyalar, aqlli sensorlar va avtomatlashtirilgan ishlov berish muhim ahamiyatga ega bo'ldi.

Ushbu global tendentsiyalar bilan kruvasan tizimlari, yuqori hidratsiyali tost liniyalari va to'liq avtomatlashtirilgan non liniyalari kabi sanoat tarmoqlari non ishlab chiqaruvchilardan kengaytirilgan sarmoya oldi.

Mahsulot liniyasining o'sishi: barcha toifalar bo'yicha kuchli ishlash

2025 yil davomida Endryu Mafu Machinery bir nechta ishlab chiqarish toifalarida sezilarli o'sishni kuzatdi.

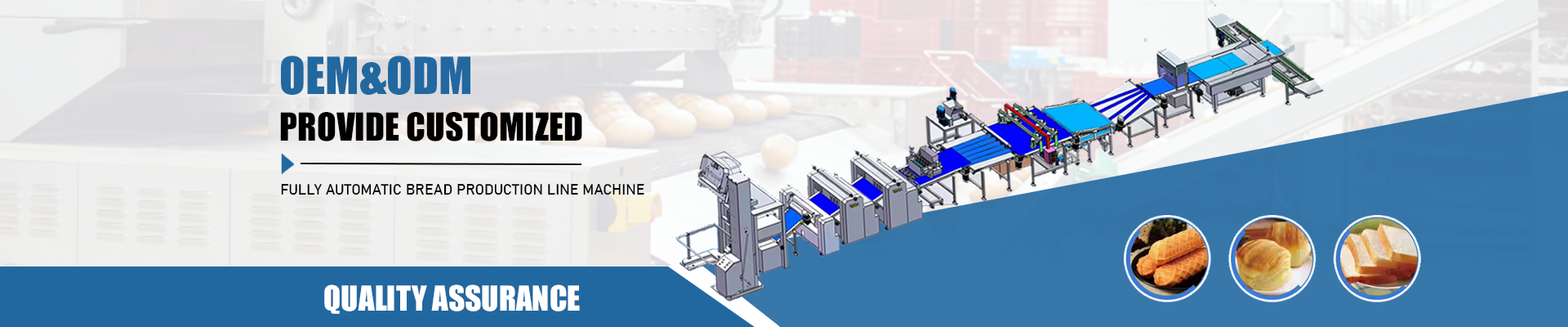

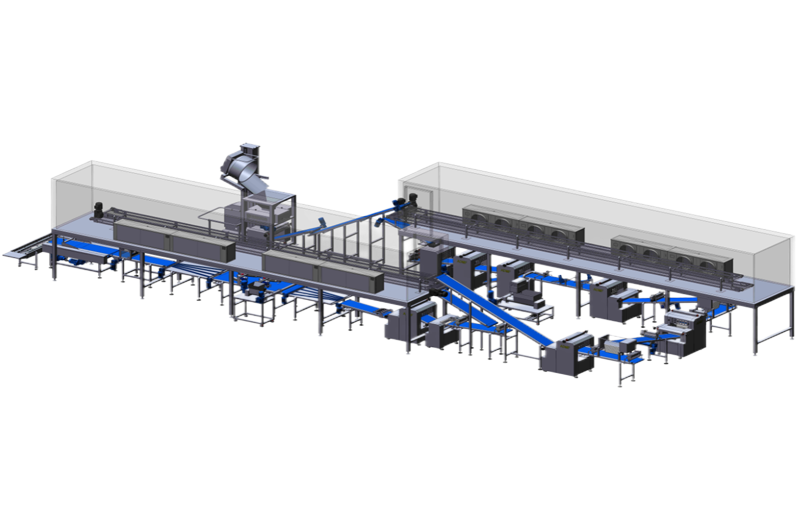

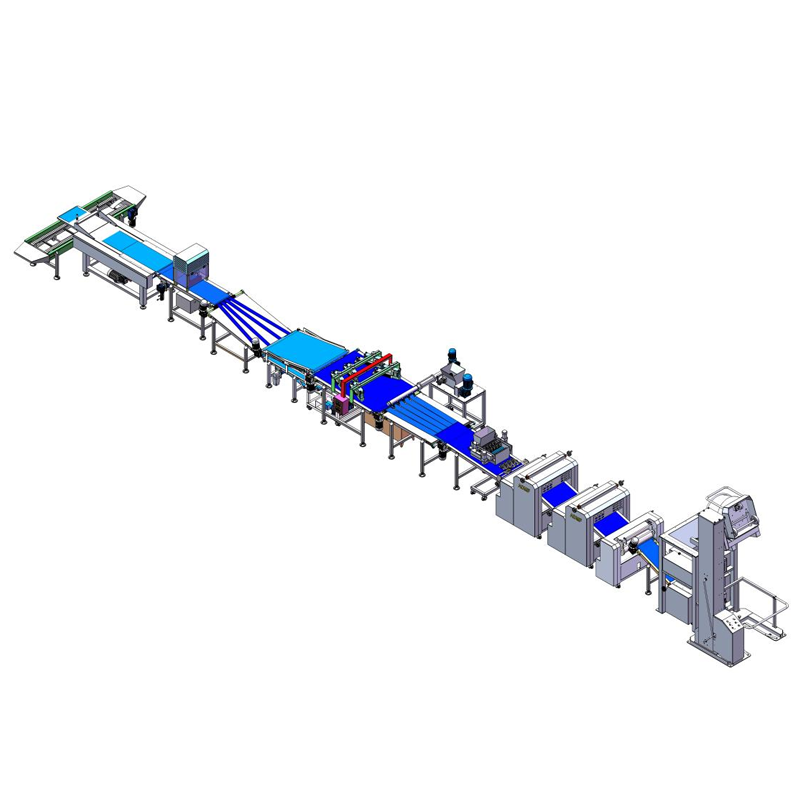

Avtomatik non ishlab chiqarish liniyasi

Rivojlanayotgan bozorlarda, ayniqsa yarim avtomatikdan to'liq avtomatlashtirishga o'tadigan zavodlarda talab ortdi.

Asosiy yaxshilanishlarga quyidagilar kiradi:

-

yanada barqaror xamir yaxlitlash

-

yaxshilangan tekshirish nazorati

-

yakuniy shakllantirishda aniqlik

-

energiya tejamkor tunnel muqobillari

Yuqori namlikli tost non liniyasi

Bu yilning eng ko'p so'ralgan qatorlaridan biriga aylandi.

Mijozlar afzal ko'rgan:

-

moment bilan boshqariladigan aralashtirish

-

yumshoq xamirni laminatsiyalash

-

yuqori namlik bilan ishlov berish barqarorligi

-

nonning balandligi va tuzilishi bir xil

Kruvasan ishlab chiqarish liniyasi

Kruasan iste'moli Yaqin Sharq, Janubi-Sharqiy Osiyo va Janubiy Amerikada keskin o'sdi.

AMF kruvasan liniyasi yangilanishlarni ko'rdi, jumladan:

-

yaxshilangan qatlam silliqligi

-

rulonni aniq shakllantirish

-

sozlanishi laminatsiya qatlamlari

-

doimiy yuqori tezlikda ishlash

Sendvich non ishlab chiqarish liniyasi

Bu toifa iste'molga tayyor mahsulotlarga talab ortib borayotgani tufayli tez kengayib bordi.

Tostlarni tozalash, yoyish, avtomatlashtirilgan to'ldirish va ultratovushli kesish kabi modullar keng qo'llanildi.

2025 Endryu Mafu Machinery kompaniyasining asosiy yutuqlari

1. Zavod quvvatlarini kengaytirish

Buyurtmalarni ko'paytirishni qo'llab-quvvatlash uchun kompaniya kengaytirildi:

Yangilangan ob'ekt yanada samarali ish jarayonini va etkazib berish vaqtlarini qisqartirish imkonini beradi.

2. Ilmiy-tadqiqot va avtomatlashtirishni boshqarishni takomillashtirish

Muhandislik jamoasi bir nechta yangiliklarni taqdim etdi:

-

yaxshilangan PLC sinxronizatsiyasi

-

xamirni tekislash algoritmlari

-

yuqori laminatsiya aniqligi

-

mexanik tebranishning pasayishi

-

kamroq ifloslanish nuqtalari bilan rivojlangan gigienik dizayn

3. Kuchli global o'rnatishlar

Yil davomida uskunalarni o'rnatish ishlari yakunlandi:

Ushbu qurilmalar o'rta kattalikdagi non zavodlaridan tortib milliy sanoat korxonalarigacha bo'lgan.

4. Maxsus buyurtma loyihalari

2025 yil bo'yicha so'rovlar ko'paydi:

-

maxsus baget shakllantirish tizimlari

-

mahalliy uslubdagi nonni shakllantirish modullari

-

yuqori tezlikda kesish dizaynlari

-

moslashuvchan sendvich moslashtirish birliklari

Bu bozorning mintaqaga xos mahsulot innovatsiyasiga o'tishini aks ettiradi.

Etakchilik xabari: Global taraqqiyot yili

“2025 yil bizga kuchli hamkorlik va doimiy innovatsiyalar muhimligini ko‘rsatdi.

Biz ko'plab mintaqalarda avtomatlashtirilgan non mahsulotlari yechimlariga bildirilgan ishonch uchun minnatdormiz.

2026-yilga kirib, biz global non sanoatiga yanada aqlli, samarali va ishonchli ishlab chiqarish texnologiyalarini yetkazib berishga sodiqmiz”.

— Endryu Mafu mashinasozlik boshqaruvi jamoasi

Bir qarashda 2025 - Asosiy raqamlar

-

120 dan ortiq mamlakatlar xizmat qilgan

-

300 dan ortiq xodimlar ishlab chiqarish, AR-GE va xizmat ko'rsatish bo'yicha

-

200 dan ortiq avtomatlashtirilgan liniyalar butun dunyo bo'ylab yetkazib beriladi

-

8 ta yangi texnologiya yangilanishi non, tost, kruvasan va sendvich tizimlari bo'ylab

-

20 000 m² zamonaviy ishlab chiqarish ob'ektlari

Bu raqamlar nafaqat kompaniyaning o'sishini, balki avtomatlashtirilgan non ishlab chiqarish uskunalariga global talabning ortib borayotganini ham aks ettiradi.

2026-yilga qarab

Kompaniya yangi texnologik yangilanishlarni tayyorlamoqda, ular quyidagilarga qaratilgan:

-

aqlli monitoring tizimlari

-

AI yordamida xamirni qayta ishlash

-

yuqori tezlikda kruvasan hosil qilish

-

takomillashtirilgan tarqalish va ultratovushli kesish

-

energiya tejaydigan mexanik dizayn

-

rivojlangan xalqaro xizmatlarni qo'llab-quvvatlash

Maqsad - aqlliroq, barqarorroq va global bozor ehtiyojlariga ko'proq moslashadigan non ishlab chiqarish uskunalarini etkazib berish.

TSS

1. 2025 yilda eng kuchli sotilgan ishlab chiqarish liniyalari qaysilar edi?

Yuqori hidratsiyali tost liniyalari, kruvasan liniyalari, sendvich liniyalari va avtomatik non liniyalari.

2. Bu yil qaysi bozorlar eng tez o'sdi?

Yaqin Sharq, Janubi-Sharqiy Osiyo, Afrika va Sharqiy Yevropa.

3. Endryu Mafu bu yil zavodini yangiladimi?

Ha - ishlov berish, yig'ish, QC va saqlash hajmi kengaytirildi.

4. Qanday texnik yutuqlar joriy etildi?

PLC yangilanishi, xamirni qayta ishlash usullari, laminatsiyaning aniqligi va ultratovushli kesish yaxshilanishi.

5. 2026 yil uchun nimalarga e’tibor qaratilgan?

Aqlli avtomatlashtirish, raqamli monitoring, yuqori samaradorlik, energiyani tejovchi dizaynlar va moslashtirilgan yechimlar.