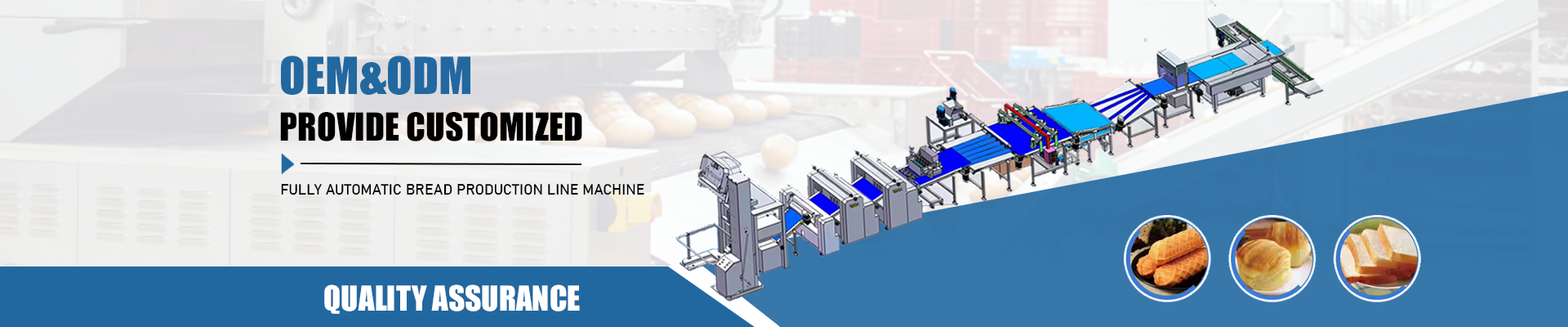

Mashiinnada Andrew Mafu ayaa bilaabay khadka Soo saarista Croissant Si Toos ah Si Buuxda ah: Dib u qeexida Automation-ka Roodhiga iyo Saxnaanta

Andrew Mafu Machinery Import & Export Co., Ltd. (ADMF), oo ah hogaamiye caalami ah ee farsamaynta roodhida garaadka leh, ayaa si sharaf leh ugu dhawaaqa sii deynta Khadka Wax-soo-saarka Croissant oo Si Toos ah u Buuxsan, loogu talagalay in lagu beddelo wax soo saarka macmacaanka warshadaha iyada oo loo marayo saxnaanta gees-goynta, hufnaanta sare, iyo nidaamyada xakamaynta caqliga leh.

Iyada oo baahida caalamiga ah ee alaabada roodhida leedsan sida karoobada, keega Danishka, iyo keega la dubay ay sii kordheyso, rootiyaasha ayaa raadinaya xal toos ah oo ilaalinaya tayada farsamada iyadoo si weyn u kordhineysa wax soo saarka. Andrew Mafu's buundooyinka khad kororsi ee ugu dambeeyay ee farqiga u dhexeeya - isku darka farsamada gacanta iyo otomaatiga.

Waa Cusub ee Wax soo saarka Croissant

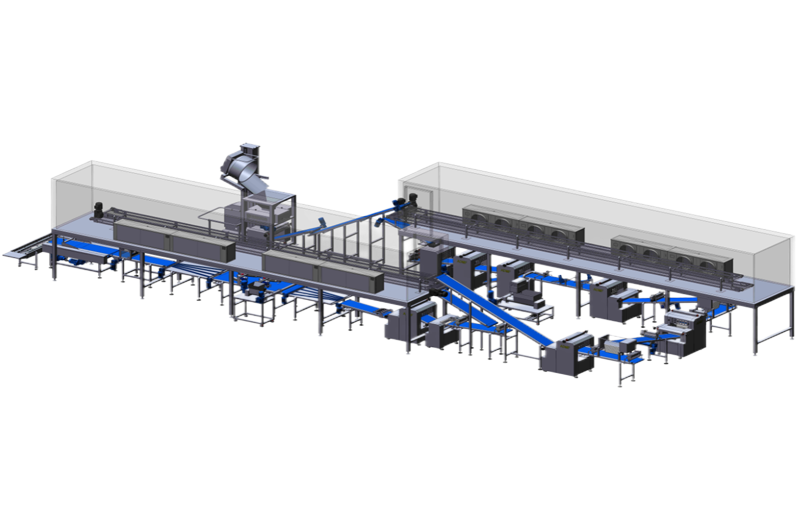

The ADMF Si Buuxda Oo Toomaatig ah Wax Soo Saarka Croissant (Model ADMFLINE-001) wuxuu dhexgeliyaa isku dhafka cajiinka, rogrogmada, laalaabida, goynta, goynta, iyo u qaabaynta hal hab oo aan toos ahayn. Nidaamku waxa uu ku celceliyaa farsamooyinka soo jireenka ah ee Faransiiska isagoo hubinaya joogteynta heerka warshadaha.

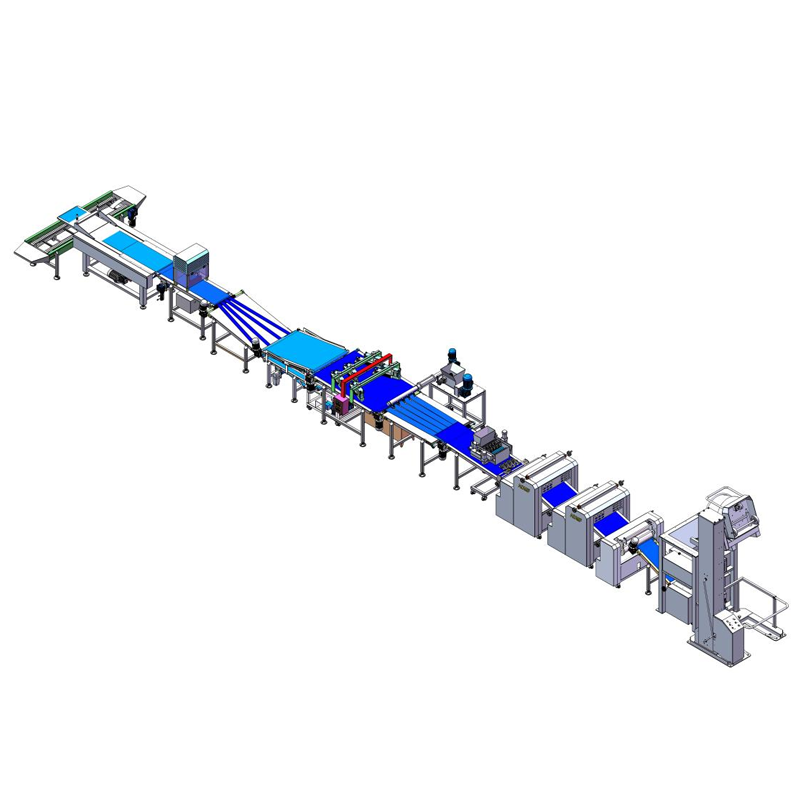

Khadkan hal-abuurka leh ayaa soo saari kara 4,800 ilaa 48,000 croissants saacaddii, iyadoo ku xiran qaabeynta iyo cabbirka alaabta. Iyada oo la raacayo rullaluistuyada saxda ah ee servo-driven iyo goobaha lagu hagaajin karo, roodhida ayaa si fudud u dejin kara dhumucda cajiinka, lakabyada subagga, iyo qaababka si ay u abuuraan badeecado u dhexeeya mini croissants ilaa macmacaanka la buuxiyey.

Tilmaamaha Muhiimka ah iyo Farsamooyinka Farsamada

1. Nidaamka Lamination-sare ee saxda ah

Nidaamku waxa uu isticmaalaa rullalayaal heersare ah iyo tignoolajiyada laalaabida kuwaas oo si siman u qaybiya lakabyada cajiinka iyo subagga oo leh dhumuc la hagaajin karo, iyada oo ilaalinaysa muuqaalka dhabta ah ee jilicsan ee croissants.

2. Xakamaynta xaashida cajiinka ee lagu maamulo Servo

Matoorada sare ee servo waxay keenaan meelaynta xaashida cajiinka saxda ah iyo xiisad joogta ah, hubinta isku mid ahaanshaha alaabta iyo yaraynta qashinka.

3. Goynta iyo Qaabaynta Hababka badan

Caaryada la cusboonaysiin karo iyo isu imaatinka daabku waxay soo saaraan cabbirro kala duwan oo croissant ah. Qaybaha duubista tooska ah waxay u qaabeeyaan bilaha qumman ee xawli sare leh, iyagoo ilaalinaya muuqaalka dhabta ah ee gacanta lagu sameeyay.

4. Isku darka caddaynta, dubista, iyo qaboojinta doorashooyinka

Xaruntu waxay si aan kala go 'lahayn ugu xidhaa qolalka wax lagu caddeeyo iyo foornooyinka tunnel-ka si loo helo xal dhammays tiran. Gaadiidleyda qaboojinta ee ikhtiyaarka ah iyo nidaamyada baakadaha waxay xaqiijiyaan habsami u socodka socodka qulqulka.

5. Intelligent PLC + Nidaamka Xakamaynta shaashadda

Hawl-wadeenadu waxay dejin karaan xuduudaha sida dhumucda cajiinka, xaglaha jarista, iyo xawaaraha wax soo saarka oo leh is-dhexgal fudud. Xusuusta cunto karinta waxay u oggolaanaysaa beddelka alaabta degdegga ah.

6. Nadaafad iyo Fudud in la ilaaliyo

Laga dhisay gebi ahaanba bir aan lahayn heer cuntoNidaamka waxaa ka mid ah boodhka tooska ah, suumanka la saari karo, iyo hababka nadiifinta degdega ah ee nadaafadda sare iyo wakhtiga dayactirka oo yaraaday.

Waxtarka Tamarta iyo Heerarka Caalamiga ah

Khadka wax soo saarku wuxuu shaqeeyaa qiyaastii 20 kW ee awoodda guud, Bixinta waxqabadka sare leh isticmaalka tamarta yar. Xakamaynta dhaqdhaqaaqa isku xidhan waxay yaraynaysaa culayska farsamada waxayna kordhisaa cimriga mishiinka.

Dhammaan qalabka ADMF waa kulmaan Heerarka CE iyo ISO 9001, hubinta u hoggaansanaanta xeerarka badbaadada cuntada iyo nadaafadda caalamiga ah.

Is dhexgalka aan Xumaan lahayn iyo Xalka Warshada Casriga ah

Xariiqda croissant waxay la mid noqon kartaa qalabka kale ee ADMF sida Isku qasayaasha cajiinka, Subaga Laminators, Qaboojiyayaashaiyo Mashiinada dhaqida iyo qalajinta saxaaradda, abuurista nidaam wax-soo-saar joogto ah.

Adigoo qaadanaya Andrew Mafu's Nidaamka deegaanka ee rootiga casriga ah, Roodhiyayaashu waxay la socon karaan xogta wax soo saarka wakhtiga dhabta ah, waxay wanaajiyaan isticmaalka tamarta, iyo hagaajinta socodka shaqada - u soo dhawaanshaha warshadaha 4.0 wax soo saarka caqliga leh.

La Xaqiijiyay Guusha iyo Gaadhsiinta Caalamiga ah

ADMF's technology croissant waxaa si guul leh u qaatay soosaarayaasha rootiga ee gudaha Indonesia, Malaysia, Saudi Arabia, iyo Italy. Macaamiishu waxay ammaaneen joogtaynta, qaabaynta xawaaraha sare, iyo nashqada isticmaale-saaxiibtinimo.

Mudaaharaadyadii ugu dambeeyay ee warshadda ee Zhangzhou ayaa soo jiitay dareenka dhowr kooxood oo waaweyn oo roodhida, kuwaas oo qaar badan oo ka mid ah ay muujiyeen xiisaha ay u qabaan abuuritaanka iskaashi muddo dheer ah Andrew Mafu.

Kartida Wax-soo-saarka iyo Sare ee R&D

Andrew Mafu wuxuu ka shaqeeyaa a 20,000 m² xarun wax soo saar Zhangzhou, Gobolka Fujian, oo ay ka shaqeeyaan in ka badan 100 khabiir xagga naqshadaynta farsamada, otomaatiga, iyo injineernimada habka rootiga.

Shirkaddu waxay haysaa shatiyo badan mashiinka rootiga iyo rootiga oo si joogto ah u maalgeliya naqshadeynta dhijitaalka ah, jilitaanka, iyo tijaabinta si loo riixo xadka otomaatiga roodhida.

"Automation-ku waa aasaaska dubista casriga ah," ayuu yiri agaasimaha farsamada ee shirkadda. "Khadkayaga croissant-ka ah ee si toos ah u toosan wuxuu ka caawiyaa roodhida inay gaaraan tayo joogta ah iyagoo kor u qaadaya wax soo saarka si ay u daboolaan baahida suuqa."

Mashiinnada Andrew Mafu waxa ay weli ka go'an tahay inay ka caawiyaan roodhiyaasha adduunka oo dhan inay dhisaan khadad wax soo saar ka hufan, nadiif ah, oo hufan - laga bilaabo diyaarinta cajiinka ilaa dhammaystirka dahabka lagu dubay.

Su'aalaha Inta Badan La Isweydiiyo (FAQ)

Q1: Waa maxay awoodda wax-soo-saarka ee Khadka Wax-soo-saarka Croissant oo dhammaystiran?

A1: Iyada oo ku xidhan qaabeynta khadka iyo cabbirka croissant, wax soo saarka ayaa u dhexeeya 4,800 ilaa 48,000 xabbo saacaddii.

Q2: Mashiinku ma xamili karaa noocyada cajiinka iyo buuxinta kala duwan?

J2: Haa. Khadku wuxuu farsamayn karaa cajiinka la shiilay ee subagga ku salaysan iyo cajiinka ku salaysan margarine labadaba. Waxay taageertaa buuxinta kala duwan sida shukulaatada, kareemka, ama koollada khudradda.

Q3: Intee in le'eg ayay qaadataa rakibaadda iyo tababarka?

A3: Sida caadiga ah, rakibidda iyo tababarka goobta ayaa lagu dhammeyn karaa gudaha 2-4 toddobaad, iyadoo ku xiran qaabka warshadda iyo khibradda hawlwadeenka.

Q4: Miyuu xariiqda croissant ku xidhi karaa qalabka kale?

J4: Dhab ahaantii. Waxay si habsami leh ula midowdaa cadayayaasha ADMF, foornooyinka tunnel-ka, nidaamyada qaboojinta, iyo mashiinnada baakadaha si otomaatig ah u socodka shaqada.

Q5: Waa maxay adeegyada iibka kadib uu bixiyo Andrew Mafu?

A5: ADMF waxay bixisaa 24/7 taageero farsamo, Baadhista fogaanta, sahayda qaybaha firaaqada, iyo hagida dayactirka nolosha si loo hubiyo waxqabadka mashiinka ugu fiican.

Q6: Ma la heli karaa habaynta?

J6: Haa. Andrew Mafu waxa uu habayn karaa cabbirka mishiinnada, sifooyinka alaabta, iyo qaabaynta qaabaynta iyadoo loo eegayo booska wax soo saarka ee macmiil kasta iyo suuqa bartilmaameedka.

Macluumaadka Xiriirka

Andrew Mafu Machinery Import & Export Co., Ltd.

📍 Degmada Longhai, Magaalada Zhangzhou, Gobolka Fujian, Shiinaha

🌐 Website: https://www.andrewmafugroup.com/

📧 Email: [email protected]

📞 Tel/WeChat/WhatsApp: +86 184 0598 6446

By ADMF